Automated Workholding Solutions for Aerospace Manufacturing

Why choose ROEMHELD for your Aerospace applications?

At ROEMHELD and Carr Lane Manufacturing we understand the demands of the aerospace industry, not only because of our decades of experience manufacturing aerospace tooling components and fixtures but also for setting the standard for today’s rigorous safety and design specifications of aerospace components. Our power workholding devices allow users faster clamping and faster machining without sacrificing quality. Our engineers can provide customized workholding solutions for your aerospace applications that will streamline your production process and create consistent clamping while reducing labor costs.

What are all the Aerospace Solutions ROEMHELD provides?

ROEMELD Solutions break up into four categories for aerospace applications. Please click below to learn more about each product line and the solutions we can provide,

Why use automated workhlding products for your Aerospace applications?

AUTOMATION – Power-operated elements provide more control and a wide range of operations within a workholding system. Once adjusted, each product consistently clamps or holds. Powered work supports automatically adjust to minor workpiece irregularities. In addition, power workholding systems can operate multiple clamps and other devices in sequence to accomplish a multistep fixturing task.

SPEED AND SAFETY – Power Workholding Components greatly reduce loading times and are particularly effective for high-volume runs. Although initial costs are higher than with mechanical workholding, self-contained hydraulic workholding products are more efficient because fewer clamps (and accompanying personnel to operate them) are required. By replacing repetitive manual clamping, power workholders reduce operator fatigue. They allow remote control of inaccessible fixturing. Most systems also feature backup controls for added safety in case of power failure.

UNIFORM CLAMPING FORCE – Since power workholders are controlled by a power source, the strength and fatigue of the operator have no effect on clamping force. Once set, force remains constant. And when more or less force is required for the next setup, the same clamps or positioners can beadjusted for those specific conditions.

SIMPLIFIED OPERATION -When operators have less physical labor in clamping and unclamping, they can run more machines and produce more. More workpieces can be loaded on fixtures for a given production cycle, which lengthens individual steps and requires less attention from the operator. Many types of power workholding can be performed by less-skilled workers.

N/C COMPATIBILITY – Versatile power workholding does not require design specialists. The same tool designer who designs the workholder can also design the clamping system. With their small size, Roemheld components are easy to locate. Standard fittings connect easily and ensure positive sealing.

COMPACTNESS -Roemheld power components are designed to fit easily on fixtures. Since they function well at fluid pressures up to 7500 psi, their smaller design can still provide high clamping forces. Small power clamps often allow loading more workpieces on a fixture because the clamps can be positioned closer together. A result is increased productivity through more parts per cycle.

Find Your Local Regional Representative HERE >

>CNC Machine Vises & Jaws<

Click below!

ROEMHELD offers a wide assortment of precision machine vises for CNC machines and milling operations with horizontal and vertical mounting options. Fully hydraulic and hydra-mechanical versions of these machine vises provide the consistent clamping force required for high-speed machining, significantly reducing operator fatigue. Precision vises are designed to hold many different workpieces, and come in three versions: 5-axis vises, machine vises, and self-centering vises delivering clamping forces up to 22,500 lbs.

|

NEW PC-80 Vise

|

PC80 Clamping system features a simple, compact all-steel design, and includes clamping jaws with a dovetail shaped serrated gripping feature. The all-steel design provides the highest force, most rigid, design in 5-Axis vises. The Jaw assembly is simple to remove ensuring quick and easy cleaning and maintenance. The PC80 features several mounting options including the use of competitor Zero-Point 52mm pins or the use of a Quintus Pull-Down Bolt. The sides of the base include grooves for permanent installation with clamping claws. Watch a Video!

|

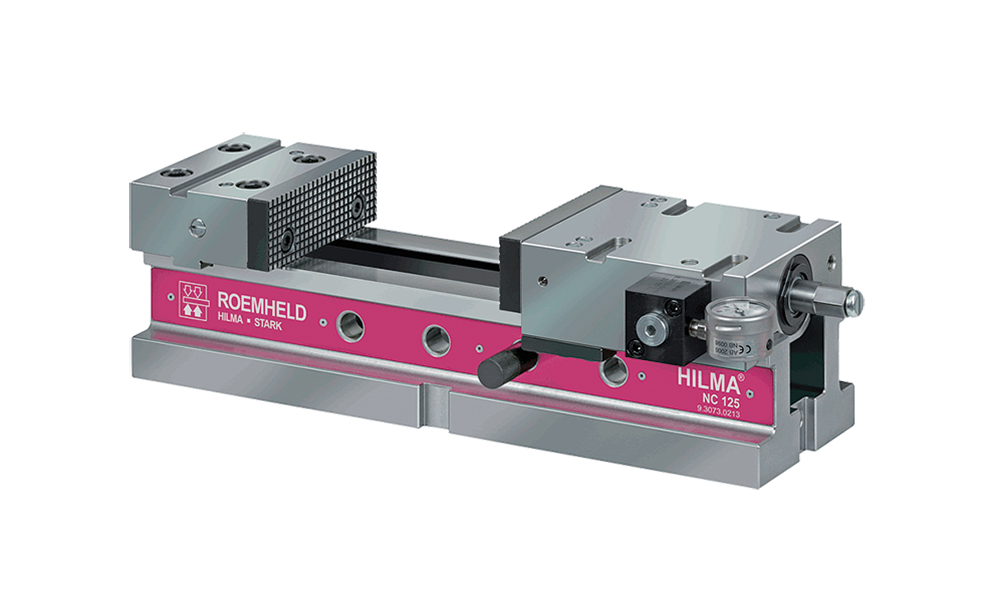

NC Series

|

The hydra-mechanical CNC machine vise shown here is manually operated, with final high force applied easily using an internal hydraulic power assist (no power unit required). Available in three sizes, with the following jaw widths: 100mm, 125mm, 160mm. NC-series vises are ideal for precision, high-production machining on vertical machining centers. Fixed and sliding jaws are precision ground to accept top-jaw tooling. Finest-quality construction for excellent rigidity and durability.

|

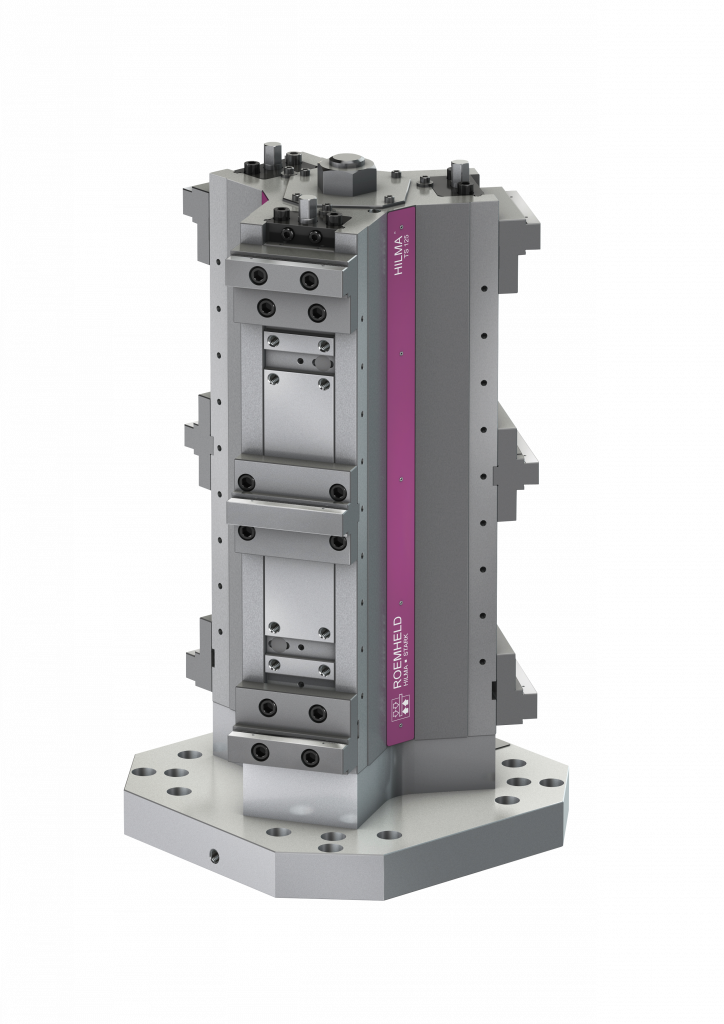

TS Tri-Star Vise

|

TS tower workholding systems are used on horizontal machining centers, in vertical machining in connection with 4th axis, but also on 5-axis machining centers. The applications range from manually equipped machines to pallet stations and fully automated systems. The patented guidance and sealing principle works without any delicate sheet metal covers or plastic wipers. The centrally arranged fixed jaw as a central jaw is without load and has absolute zero point stability. The workpieces are positioned close to each other, reducing the travel paths of the machining center to a minimum. The mechanical operation enables clamping with low and reproducible clamping forces. These characteristics turn the tower workholding systems TS into a flexible standard fixture for a wide variety of applications in modern production.

|

Double Clamping System DS

Download Data Sheet |

The Machine Vise, Double Clamping System DS, is mechanically or hydraulically operated, for single and row clamping. They have a top jaw, with horizontal or vertical mounting, and can clamp up to 4 parts with floating central jaw. A one-sided lead screw operation with 3rd hand function makes loading and unloading of the workpiece easy. Jaw widths include 100, 125, and 125 L (mm). They have a max clamping force in 4 sizes.

|

– View all CNC Machine Vise Products HERE –

> Power Workholding Systems<

Click below!

ROEMHELD power workholding devices allow users faster clamping and faster machining without sacrificing quality. Power workholding devices such as those offered by ROEMHELD offer significant advantages over manual clamping, including remote clamp operation, reduced operator fatigue, automatic sequencing, compactness, and increased machine-tool capacity. Hydraulic workholding solutions from ROEMHELD include a variety of power clamps such as Swing Clamps and Extending Clamps as well as Threaded Cylinders, Block Cylinders, Power Work Supports, Fixture Clamps, Vises, Hydraulic power sources & valves as well as a full line of fittings and accessories. Learn more about the full line of power workholding solutions offered by ROEMHELD below.

|

Automation Swing Clamps

|

This special series of double-acting Swing Clamps is designed for automated high production, featuring a reinforced swing mechanism to ensure positive arm position, and an extended helix rod for built-in pneumatic or electrical position-monitoring capability. Automation-type clamps are a further development of our proven Swing-Clamp line to improve safety in process-linked clamping systems. These Swing Clamps are ideal when it is essential to know the exact timing of swing-arm position for unrestricted workpiece loading and unloading. They are particularly suited for: clamping fixtures with workpiece loading via handling systems; transfer lines; test systems for motors, gears, and axles; automated manufacturing systems; and assembly lines. Available in three clamp sizes, double-acting only, in the three types shown below: Top Flange, Flange Base & Threaded Cartridge.

|

|

Hydraulic Work Supports

|

This series of threaded-body work supports provide considerable load capacity at lower hydraulic pressures, allowing direct connection to the low-pressure hydraulic system of a machine tool. Work Supports automatically adjust to the proper height for supporting a workpiece, then lock securely to become fixed rests. Fluid-advanced Work Supports provide extra loading clearance and are ideal for workpieces that are too light to depress a spring-loaded plunger. These Threaded-Body Work Supports are amazingly compact. Manifold mounting capability allows space-saving low-height installation. Highly corrosion resistant with a stainless steel plunger and internal components. Metallic wiper and FKM wiper together provide excellent protection against dirt and coolant entry. Hardened contact bolt furnished.

|

|

Mini Compact Clamp

|

Compact Clamps have a sturdy lever mechanism that pivots into a clamping position. These clamps are extremely compact both in footprint and overall height. The clamping lever pivots a full 90° for clear loading even when using custom long clamping levers. Ideal for clamping in narrow recesses. The top-flange cartridge-type version shown here is designed specifically for space-saving manifold mounting. Thanks to the small housing diameter of only 22mm, this clamp can be installed in places where up to now there was insufficient space for a hydraulic clamping element. The minimum centerline distance between clamps is 28 mm. Available in one clamp size, double-acting only. Clamping force at 2900 psi with standard clamping arm.

|

>Zero Point Mounting Solutions<

Click below!

Reduce fixturing setup time up to 90 percent with ROEMHELD Stark’s Zero Point Mounting Systems. Existing fixtures can be easily adapted to the system, which allows for fast payback, longer fixture life, and highly accurate positioning and repeatability. This comprehensive zero-point mounting system utilizes clamping components and insertion nipples, which provide an immediate zero-point orientation, allowing faster and more accurate fixture setup and changes to increase machine capacity. Change-over can be accomplished in 20 sec.

|

STARK Easy Click

|

STARK easy click is a mechanical fast closing clamp that clicks in and stays in place without the supply of energy. The release is simply by means of an air connection at a pressure of 4–8 bar. STARK easy click is used for cutting and non-cutting machining.

|

|

STARK M-Tec

|

The SPEEDY metec is a solid, mechanical zero point mounting system that enables straightforward and economical zero point mounting solutions.

|

|

Drop Zero

|

DropZero® Modular Zero-Point System enables you to completely machine a workpiece in one setup, significantly reducing setup time and fixturing costs. With a few quick turns of a wrench, DropZero® clamping modules locate, support, and securely clamp the workpiece from underneath, providing full machining access to 5 sides.

|

> Assembly & Handling Solutions<

Click below!

ROEMHELD’s assembly systems can be combined in numerous ways for the safe and efficient handling of light to heavy loads in assembly operations. Various modules provide horizontal and vertical rotating, tilting, and lifting of workpieces with mechanical, hydromechanical, or electric operation. Each module can be used individually since they are independent functional units, or several can be combined together to create a multi-functional unit.

|

Lifting Column

|

Precision lifting and lowering of your workpiece. Electric and self-contained hydraulic versions. Electric versions can be synchronized. Telescoping versions available too. Maximum weight is 100 – 600 kg (225 – 1,350 lbs). Maximum stroke is 200 – 1000 mm.

|

|

Modular Units

|

Combine modular units for safe, efficient handling. Achieve rotating, tilting, and lifting of workpieces, and use with carts, floor modules, plates, clamps, or adjustable tables.

|

– View all Assembly & Handling Products HERE –