Drop Zero

Drop Zero

Modular Zero-Point System

Features

• Reduces setup time and fixturing costs

• Modular design works with all of CLM’s ½” and 5/8” modular tooling.

• Can also be used with non-modular tooling

• Elevates workpiece for machine spindle clearance

• Access to all 5 sides of the part

• Stackable for added clearance

Check Price & Availability on CarrLane.com

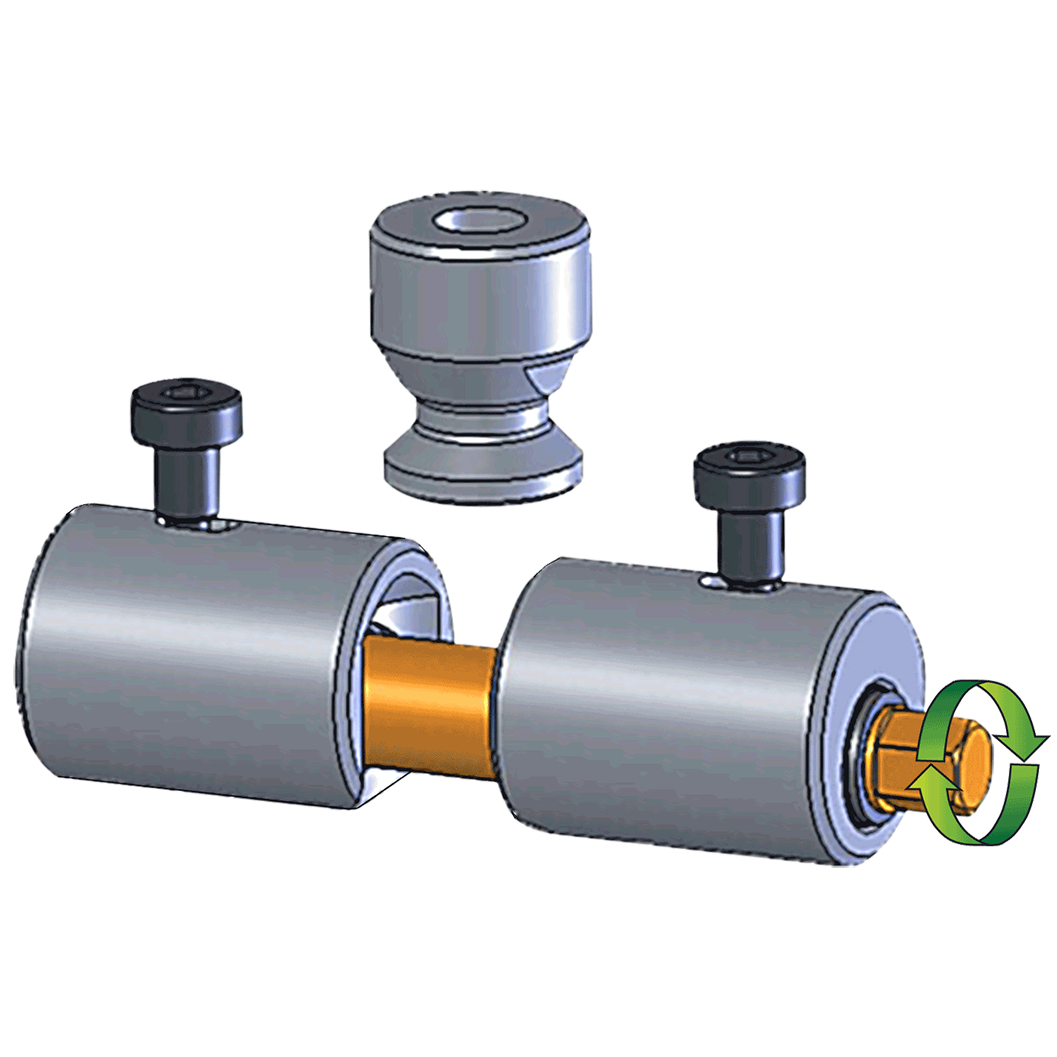

Our new DropZero® Modular Zero-Point System enables you to completely machine a workpiece in one setup, significantly reducing setup time and fixturing costs. With a few quick turns of a wrench, DropZero® clamping modules locate, support, and securely clamp the workpiece from underneath, providing full machining access to 5 sides.

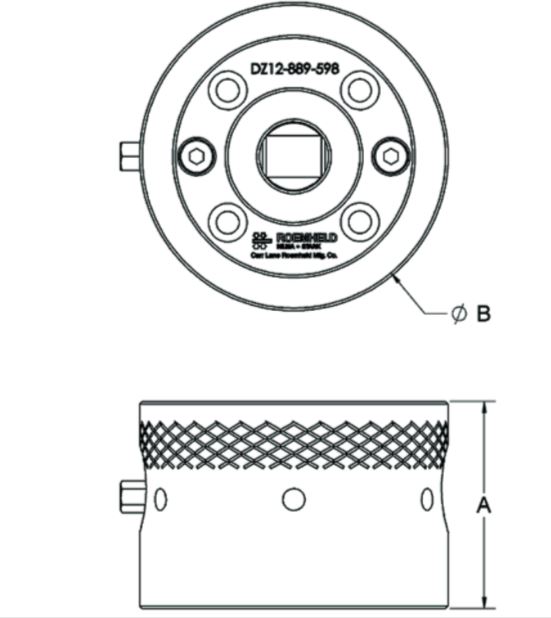

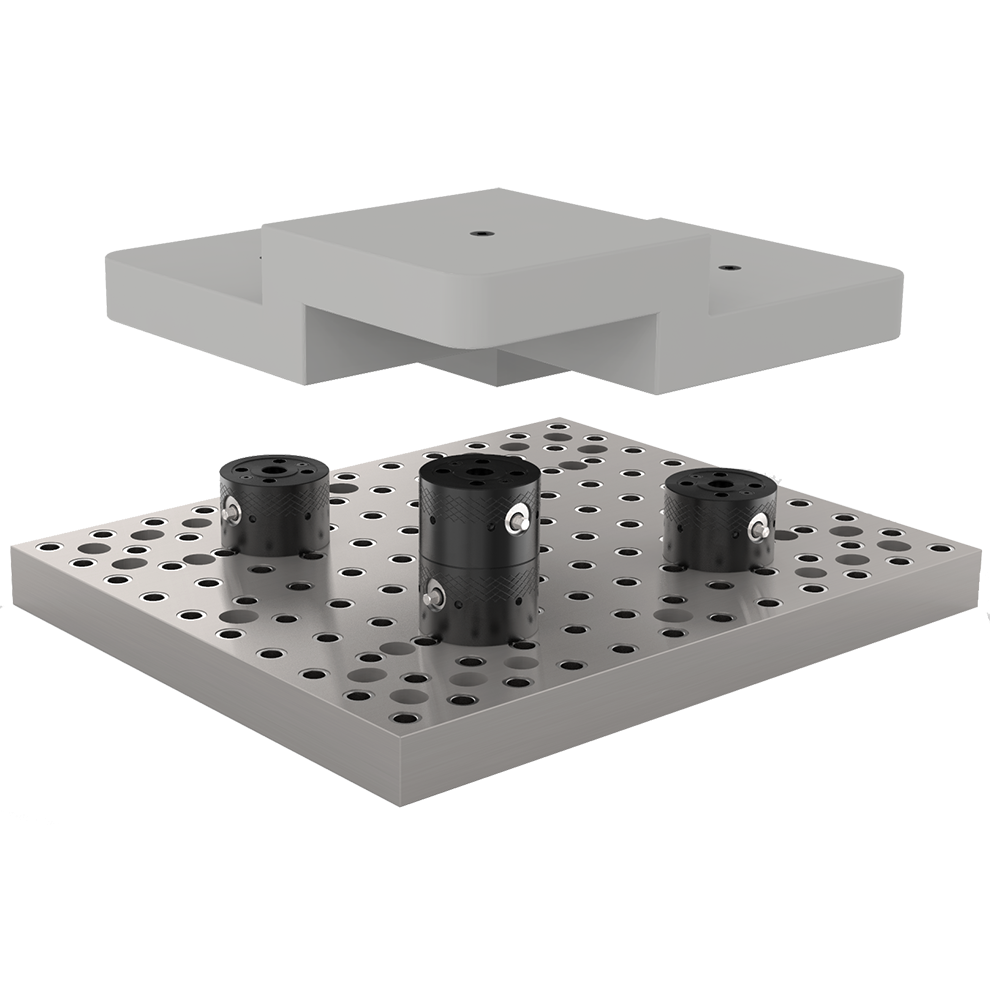

Clamping modules can be mounted exactly where required, anywhere on the fixture plate. These modules fit perfectly on all of Carr Lane’s 1/2” and 5/8” modular tooling plates and blocks, but can also be used with non-modular tooling. Clamping modules elevate the workpiece for machine-spindle clearance, and are stackable for extra height.

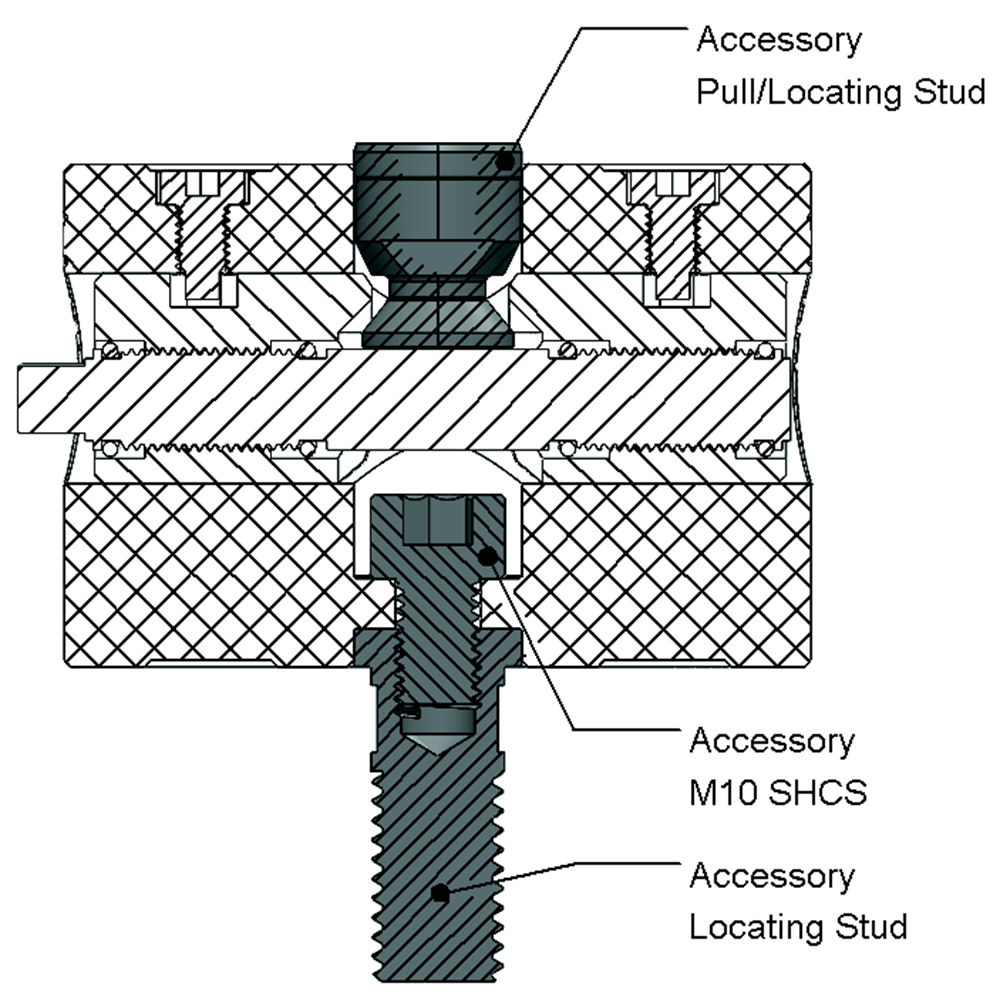

Pull-down studs must be fastened to the underside of the workpiece. Most setups require one zero-point stud (for primary two-axis location), one diamond stud (for single-axis location), and one or more floating studs (for additional support and clamping without location).

DropZero clamping modules fit perfectly on all of Carr Lane Mfg’s 1/2” and 5/8” modular tooling plates and blocks. Clamping modules elevate the workpiece for machine-spindle clearance, and are stackable for extra height.