WEBINAR RECORDING Sensory Clamping Devices for Safe and Efficient Workpiece Machining Optimization of the manufacturing process Increase in productivity Increase in flexibility Increase in throughput Detecting errors and rejects before machining starts Monitoring the machining process Increase in process reliability High system availability through condition-oriented maintenance

Latest News

New arch clamp for presses and forges

Market leader for die clamping technology expands its range of wedge clamps The new arch clamp is designed to be exceptionally sturdy and safe for use on presses and forges. The clamping technology specialist ROEMHELD expands its multi-member wedge clamp family with this clamp. The clamping element is named after the arch-shaped clamping bolt…

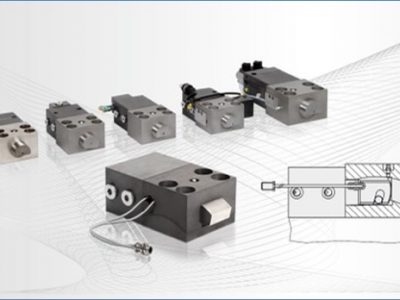

Sensor clamping technology detects defective blanks and monitors production.

BY: ROEMHELD Gruppe ROEMHELD Gruppe collaborating with partner AUGUST WENZLER MASCHINENBAU GmbH on new sensory clamping device concept. For machining of workpieces to perform efficiently, the focus is often on optimizing the machining equipment and the clamping device used with its clamping elements. There are many influencing variables, but the initial situation is largely determined…

Ergonomic Change in a Limited Space

Article from ROEMHELD Gruppe Kunststoffe International By F. Stephan Auch Shuttle Table Equipped with Hydraulic Ball Bars and Electro-Hydraulic Lifting Platform. There are some die transport carts on the market, usually models with low functionality. Few carts are optimized for a mold change, and in limited spaces or with high loads, most of them…

ROEMHELD Announces New CNC Machine Vise

Article from ROEMHELD North America Article by: Modern Machine Shop Practical Machinist Self-centering vise from ROEMHELD handles prismatic and round parts. Fenton, MO — PC 80 Clamping System is a manual vise that comes in two styles, fixed jaw and self-centering. It features a simple, rigid, all-steel design, and includes clamping jaws with a dovetail…

Ergonomic Mold Changes in Limited Spaces

Article from ROEMHELD GmbH Friedrichshütte GTMA Manufacutring Resource Center By Admin Vehicle components manufacturer ElringKlinger, headquartered in Dettingen an der Erms, Germany, includes high-performance, lightweight plastic products such as oil pans and cam covers in the product portfolio it supplies to the global automotive industry. Tobias Gerst, production engineer responsible for capital equipment…

QDC Squeezes Every Drop of Productivity

By Brad Kuvin, Editor Metal Forming Magazine November, 2020 Like a thoroughbred racehorse waiting at a stuck starting gate, operators of stalled high-speed presses waiting for the completion of a die change are chomping at the bit to get to work. So, when management at electrical-contact manufacturer JAE Oregon saw an opportunity to conduct a deep dive into im proving…

Linear Actuators used for Student Therapy Beds

Case Study from Römheld GmbH Friedrichshütte By Admin The requirements for using therapy beds in school are particularly high right now: they enable aspiring masseurs and physiotherapists to work comfortably and painlessly – and also endure rough use from the students everyday work. For this reason, beds with a hydraulic drive are often…

New Swing Sink Clamps

. The Hilma Roemheld range of die clamping systems has been extended with two new larger sizes of their swing sink clamps. The new clamps will provide 25 tons and 41 tons of force per cylinder. These internal clamps can be directly mounted onto the press bed or ram when die clamping is inaccessible.…