Article from The Metalforming Machinery Makers Association By Admin Read the full article on Metalforming Machinery Makers Association ROEMHELD at the EMO focuses on digitalisation and automation of processes Clamping elements with digitalised stroke measurement and integrated sensor technology Fair novelty: STARK robot gripper with media supply and zero point clamping system The ROEMHELD…

Latest News

The Evolution of Workholding

Article from Manufacturing Engineering By Bill Koenig – Senior Editor Read the full article on Manufacturing Engineering Makers of workholding devices strive to keep up with changes in machine tools. Five-axis vises, such as Carr Lane Roemheld’s new MCP vises, are intended to rigidly hold a part while allowing increased tool access to features…

Small Clamps for Big Die Change Needs

Since most quick die change (QDC) solutions involve medium and large dies, companies with smaller dies don’t have the same clamping options. A new offering changes that. Newly introduced smaller size clamping elements by the Hilma Div. of Carr Lane Roemheld, Fenton, MO, protect dies, improve workpiece quality and increase productivity, says the company’s…

Mold clamping element boasts spring force

Article from Plastic Machinery Magazine By Admin Read the full article on Plastic Machinery Magazine A new self-locking wedge clamping element from the Hilma division of Roemheld. It applies a spring force to lock molds into injection molding machines to facilitate easier mold changes. Self-locking wedge clamping element designed to be mounted on injection molding machines…

Workholding Solutions to Reduce Costs, Increase Throughput

by ROBERT PUHR, Contributing Editor Article excerpted from Manufacturing Engineering’s Tooling & Workholding edition, Spring 2018 At the Nirvana Machine Shop on planet Perfection, every workpiece is clamped to a custom-built fixture mounted on a dedicated machine tool. Each workpiece is dimensionally identical to the one before and the one after. All the fixtures…

DropZero modular zero-point clamping system

Article from Today’s Medical Development By Admin Read the full article on Today’s Medical Development The Carr Lane Roemheld DropZero modular zero-point clamping system enables users to completely machine a workpiece in one setup. This significantly reducing setup time and fixturing costs. With a few turns of a wrench, DropZero locates, supports, and securely…

Stampers Success To Die For

Article from Metal Forming Magazine BY JOE JANCSURAK, ASSOCIATE EDITOR Clamping Nut Catalog Page

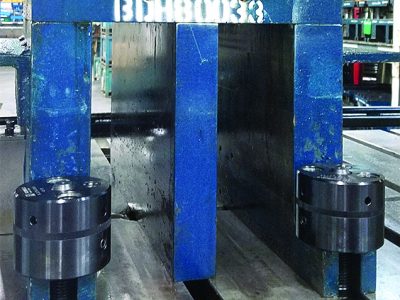

Hilma Announces New Wedge Clamp

Hilma has announced the expansion of their line of wedge clamps. Such as a new version of the clamp, featuring a patented safety notch added to the tapered clamping bolt. The notch will support the upper die in the event of a pressure loss. The clamp consists of a hydraulic cylinder block and a bolt…

Die Lifter Configurator

Online configurator for customizing roller and ball bars at https://www.roemheld-gruppe.de/productconfigurator/?lang=en / It simplifies the die lifter specification process and quickly provides a dimensioned drawing in imperial and metric units. Optimized for use on Android and Apple smartphones and tablets, the configurator is available in 14 languages. Roller and ball…

‘Rotorlock’ locking system rated for turbines up to 7 MW

Article from Wind Power Engineering Magazine. By Paul Dvorak, January, 2018 Read the full article on Wind Power Engineering Magazine New rotor locks from Roemheld USA are designed to simplify maintenance for wind power plants. The double-acting hydraulic cylinder locks the rotor blade up to 6.5 megawatts, from –30°C to +70°C. The Roemheld USA rotor…