CNC Precision Machine Vises and Jaws

ROEMHELD offers a wide assortment of precision machine vises for CNC machines and milling operations with horizontal and vertical mounting options. Fully hydraulic and hydra-mechanical versions of these machine vises provide consistent clamping force required for high-speed machining, significantly reducing operator fatigue. Precision vises are designed to hold many different workpieces, and come in three versions: 5-axis vises, machine vises, and self-centering vises delivering clamping forces up to 22,500 lbs.

|

Product Spotlight NEW PC-80 Vise

|

PC80 Clamping system features a simple, compact all-steel design, and includes clamping jaws with a dovetail shaped serrated gripping feature. The all-steel design provides the highest force, most rigid, design in 5-Axis vises. The Jaw assembly is simple to remove ensuring quick and easy cleaning and maintenance. The PC80 features several mounting options including the use of competitor Zero-Point 52mm pins or the use of a Quintus Pull-Down Bolt. The sides of the base include grooves for permanent installation with clamping claws. Watch a Video!

Purchase on Carr Lane Mfg. Co.

|

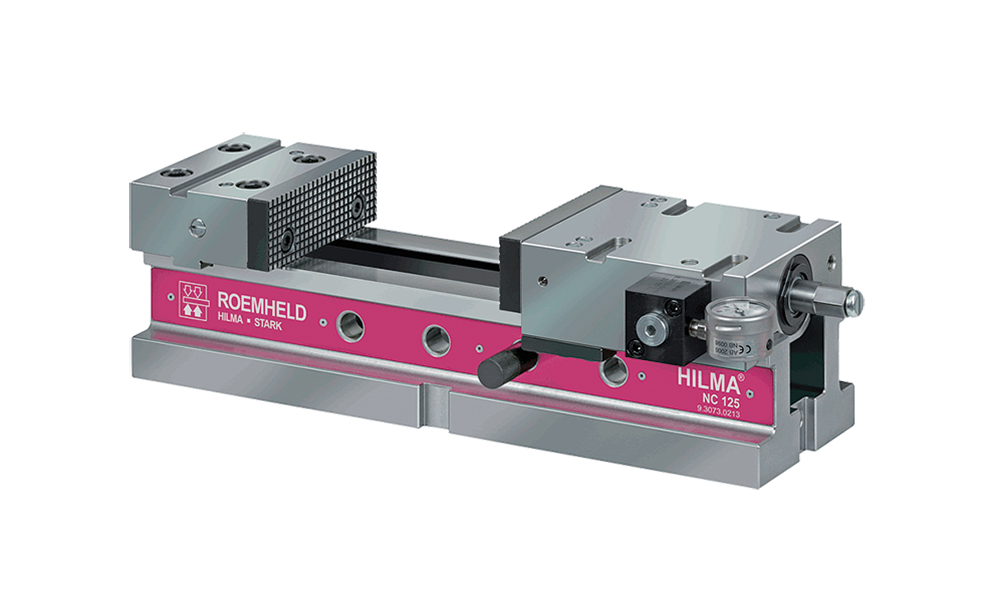

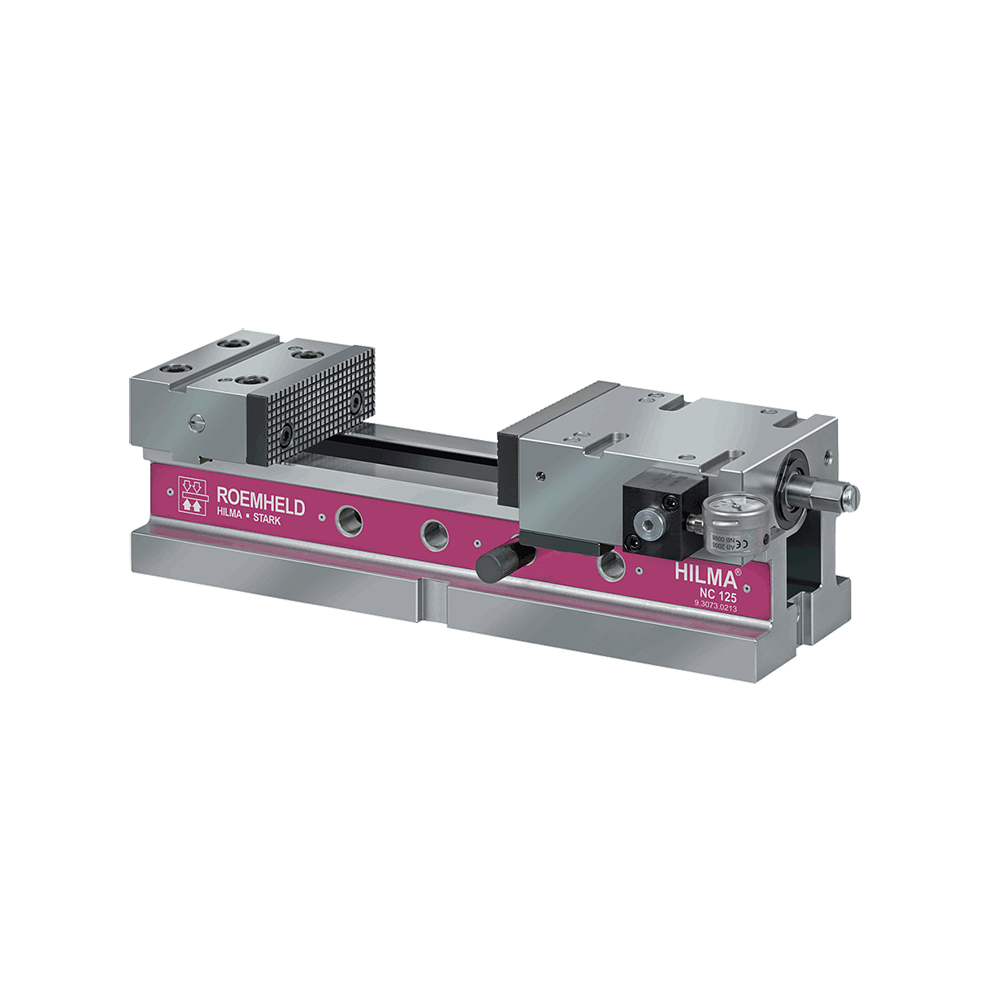

NC Series

|

High Precision Production CNC Machine Vise for use in Semi- or Fully Automatic Operation.

Purchase on Carr Lane Mfg. Co.

|

MCP Series

|

MCP-series 5-axis vises have optimal features to allow unrestricted tool access for multiple-side machining.

Purchase on Carr Lane Mfg. Co.

|

SCS Series

|

The workholding systems SCS are most commonly used for 5-axis machining.

|

|

Concentric Series

|

Concentric vises have two moving jaws that provide clamping at the exact center of the rotary table. Due to the play-free adjustment of the synchronization mechanism clamping and positioning

Purchase on Carr Lane Mfg. Co.

|

CarvesmartTM Vise Jaw System

4Learn more, including special bundle pricing! |

Carvesmart System for simplified jaw changes. The patented CARVESMART Quick Change Vise Jaw System is a complete package of dovetailed jaws for production and toolroom vises that are accurately changed in seconds. CARVESMART extruded aluminum soft jaws can be saw cut to any length. See the video!

Purchase on Carr Lane Mfg. Co.

|

Machine vises and systems for horizontal machining

single and multiple clamping systems

mechanically, mechanically/hydraulically, or hydraulically operated

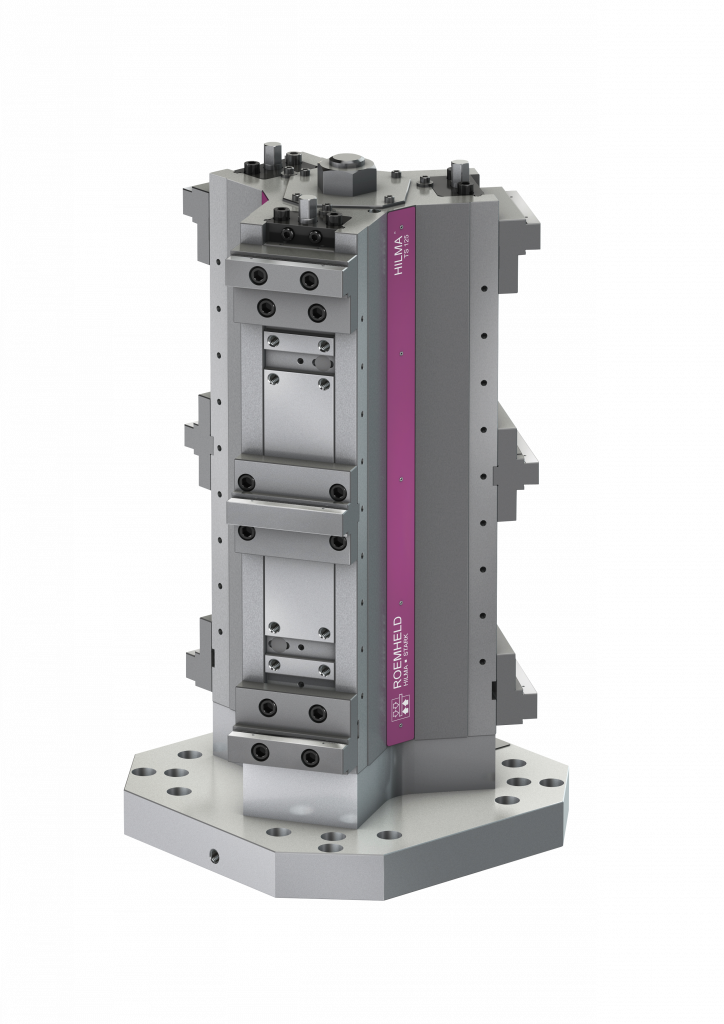

TS Tri-Star Vise

|

TS TriStar Machine Vise tower workholding systems used on horizontal machining centers, in vertical machining in connection with 4th axis, but also on 5-axis machining centers.

|

|

TS Vise

|

TS tower workholding systems are used on horizontal machining centers, in vertical machining in connection with 4th axis, but also on 5-axis machining centers.

|

|

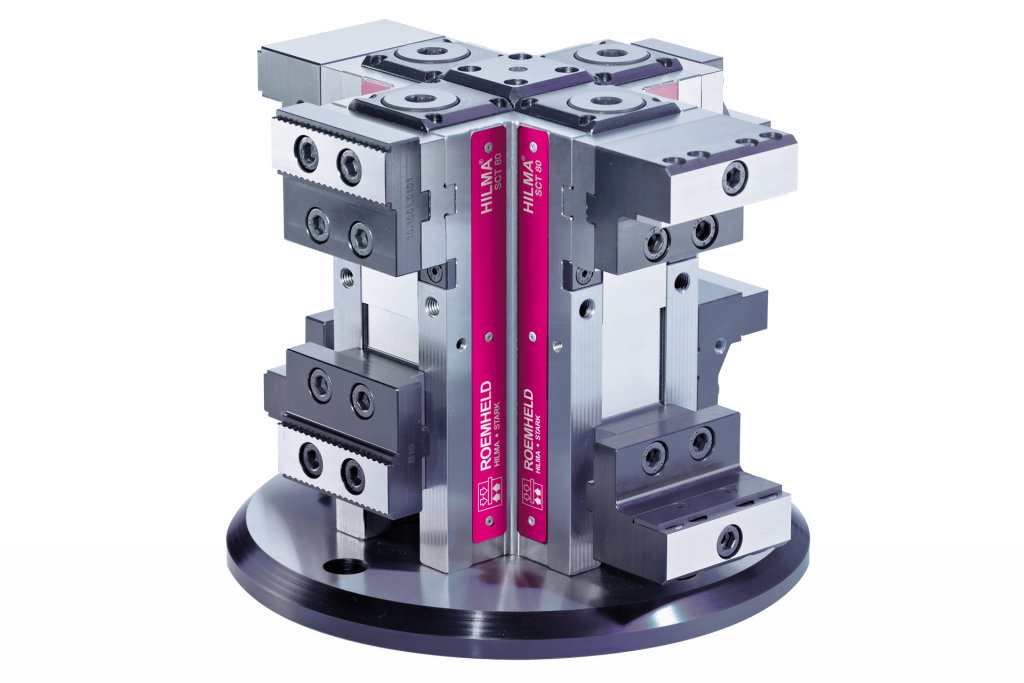

SCT System

|

Tower workholding systems of the SCT series excel by a very compact design. Thanks to the adjusting spindle arranged in the upper part of the housing, deformation in the base during clamping is reduced.

|

Carr Lane ROEMHELD has a wide assortment of CNC machine vises for nearly any application. Find the best vise here for your specific needs. Find more information below.

NEW! Carvesmart Vise Jaw System