By David L. Fischer, Engineering Manager

for the HILMA Division of Carr Lane Roemheld Mfg. Co.

Article reprinted with permission of Rubber World.

In today’s market of increased competition, short production runs and frequent mold changes, manufacturers must be alert to ideas that help increase productivity. A system to reduce the time needed for lengthy mold changes, would improve efficiencies on the shop floor and help the bottom line as well.

When discussing the justification and implementation for quick mold change there are different factors to be considered. Factors such as labor costs, machine costs, machine capacity and downtime, as well as safety and ergonomics.

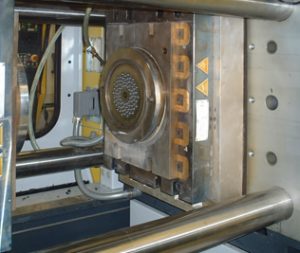

A review of the market demands, the situation in the plant and technical issues helps to define a realistic solution, quick mold change with magnetic clamping (see Figure 1).

Demands in the market

-

Increasing competition

-

Increasing pressure to control or reduce costs

-

Smaller lot sizes

-

Shorter delivery times / JIT

-

Reduced inventories

-

Limited capital commitment

-

Highly flexible production needs

Situation at the shop floor

-

More frequent mold changes

-

Mold changes are too time consuming

-

Cooling and heating of the molds in the machine

-

Different sized molds

-

Manual mechanical clamping

-

Damaged fasteners and threaded holes,

Challenge to implement faster and easier mold change

-

Minimize the “part to part” downtime

-

Unclamping and removal of the hot, used mold when the last run is complete

-

Installation of the new mold, if possible, at operating temperature

-

The new clamping system should be easily retrofitted

-

Resistance to temperatures 240°C (460° F)

-

Maintaining safe operations is necessary

Solution for the processor

-

M-TECS 210 clamps molds powerfully, quickly and reliably

-

Hot molds can be clamped or unclamped in just a few seconds

-

Molds need not be standardized to achieve rapid clamping (see figure 2)

-

Molds are clamped uniformly over their full surface

-

M-TECS 210 can be easily installed and integrated into the press

-

M-TECS 210 may be used at temperatures up to 240°C (460°F), as proven in many applications

M-TECS 210 opens up new possibilities

For reducing costs and increasing productivity

Magnetic clamping drastically cuts mold change times for the rubber industry. Mold change times can often be reduced by hours, since press downtime for heating or cooling molds in the press is no longer necessary. Using magnetic clamping technology, molds, even when hot, can be changed in just a few minutes, and clamped in seconds. This provides a high level of safety and operator ease.

The magnetic plates have a fully metallic surface (figure 3). The lack of T-slots in the plate between the heaters and the mold, with uniform full surface  clamping force yields tighter temperature tolerance in the mold, which has a positive impact on part quality.

clamping force yields tighter temperature tolerance in the mold, which has a positive impact on part quality.

All non-standardized molds can be rapidly and easily changed without modification. The all-over clamping force results in reduced mold flexure. Mold wear and maintenance costs are reduced. The magnetic plates have no moving components and are virtually maintenance-free. It may be retrofitted to existing rubber injection machines or integrated into new presses. The safety system ensures the necessary level of safety.

The magnetic clamping plates are available with integral heating platens. The system is offered in various versions, with or without heating function, for compression presses, injection presses and vacuum technology.

Productivity

- Clearly reduced set-up times

-

No heating or cooling times in the press

-

Molds are clamped in seconds with dual push-button controls

-

Clearly increased annual machine capacity

Safety and comfort

-

Completely safe in the event of power failure

-

Includes multi level safety system

-

Less time for the operator in the hot area,

-

Hand tools and clamps are not required, lowering the risk of burns (figure 4)

Quality

-

Fully metallic surface

-

Better heat transfer between the mold and the magnetic heated platen due to optimum contact, with full clamp force across the entire mold

-

No insulating T-slots

-

More homogeneous mold temperature

-

Less mold wear

-

Fewer rejects

Magnetic force

The magnetic force consists of a flat, highly concentrated magnetic field. This magnetic field penetrates the mold base plate a few centimetres (less than an inch). A mold measuring 400 x 400 mm (16” x 16”) will be clamped with a maximum clamping force of 80 kN (8 tons). For a 700 x 500 mm (20” X 28”) mold, a magnetic force of approximately 170 kN (17 tons) will be applied. The magnetic force depends on the type of surface and increases in relation to the area of the mold surface. It is uniform over the complete surface of the mold. This has a positive effect on temperature tolerance, the deformation of the die and maintenance costs.

Applications

M-TECS 210 can be used on compression and injection presses of all sizes, either for new or retrofitted to existing. The system can be used on vertical and horizontal machines. The magnetic plates are available with or without heating platens and for vacuum applications as well.

The plates are designed to suit the physical size, shape and magnetic forces required to suit the application, the process, the press and the molds to be used (figure 5).

Safety and control

The electro-permanent magnetic clamping system is safe even in the event of power failure. The magnetic clamping force is generated exclusively by the permanent magnets. Current is only used during the couple of seconds that it takes to magnetize or demagnetise the mold during mold change. During production, the controls only draw enough power to monitor the system. The integral safety system monitors the magnetic force, the mold position and platen temperature.

Operation

The operator’s control pendant is designed for two platens; upper and lower (figure 6). A multi-step process is required to magnetize or demagnetize. The operator must switch the press into set up mode, actuate a key-operated switch, and then press two push buttons simultaneously on the pendant for each mold half. Depending on the machine size, safety mats, photoelectric guards and other elements may be integrated.

Installation

Installation is very easy, and is typically done in less than a day. The magnetic plates are designed to simply bolt on. All wiring connections have plug-in type connectors. For retrofitting, a key operated switch with a simple machine interface is used to interlock the press with the MTECS system for a safe mold change.

Amortization

In the case of frequent mold changes; the investment pays off within a few months. If dies are changed one or twice a week, the system will pay for itself in a year or two.

When reviewing the system justification, the time savings and increase in productivity are important factors, but reduction costs for mold maintenance and improved part quality should also be considered.