ROEMHELD North America is thrilled to introduce the revolutionary Hilma.UC 125 machine vise, a true concentric clamp designed for versatility and efficiency in machining operations. This innovative solution, presented by STARK Spannsysteme GmbH, a proud member of the ROEMHELD Group, promises to streamline set up for different workpieces while reducing the need for multiple clamping devices across a wide range of clamping tasks.

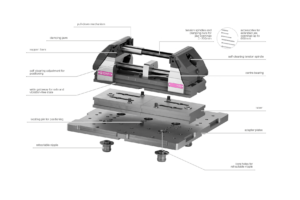

The “UC” in the clamping system’s name stands for “Universal Clamp,” as this machine vise can be easily adapted to accommodate a wide variety of workpiece geometries in just a few simple steps. The Hilma.UC 125 achieves an exceptional level of flexibility through its separable base and two parallel slides, which are effortlessly positioned using an adjustment spindle. Workpieces are securely clamped with a tension spindle, generating an impressive tensile force of 52 kN, all while a center bearing ensures precise and centered alignment with remarkable repetitive accuracy.

What sets the Hilma.UC 125 apart is its innovative clamping physics, featuring active pull-down clamping. By rotating the tension spindle, force is precisely applied to the workpiece via the outer clamping claws on the clamping jaws positioned above the workpiece stop. This ingenious flow of force prevents any stress on the base, effectively eliminating the possibility of clamp bending and ensuring the workpiece remains firmly in place.

STARK emphasizes that the jaw opening can be extended up to an impressive 600 mm, setting a new standard in the market. Additionally, a variety of clamping jaws tailored for raw and finished parts, cubic and round workpieces, are available within the modular system. This eliminates the need for further investment in new clamping devices, even as production requirements evolve.

Designed to be easily accessible from all angles, the HILMA.UC 125 machine vise enables precise 5-axis machining within a single setup. However, its versatility extends beyond 5-axis machining, making it compatible with 3- and 4-axis operations as well.

With its universal modular design, the HILMA.UC 125 opens a vast array of applications. It offers not only extensions for different clamping widths but also numerous mounting options adaptable to specific applications. The clamp can be directly placed on the machine table or integrated into a zero-point clamping system.

Furthermore, flexible adapter plates simplify the realization of various clamping tasks, making it an indispensable asset for accommodating workpieces of diverse sizes and geometries.

Guido Born, Product Manager at STARK Spannsystem GmbH, sums it up best: “Together with comprehensive accessories, the HILMA.UC 125 is a universal clamping system for workpieces of different sizes and geometries. So, one vise is enough instead of numerous systems, each with different jaw openings.”

About ROEMHELD North America: ROEMHELD North America is a leading provider of innovative Workholding solutions for the manufacturing industry. With a commitment to excellence and a focus on delivering cutting-edge technologies, ROEMHELD North America continues to empower manufacturers to achieve precision and efficiency in their operations.

About STARK Spannsysteme GmbH: STARK Spannsysteme GmbH, a member of the ROEMHELD Group, is a renowned leader in providing high-quality clamping, Zero-Point and machining vises solutions for the machining industry. With a strong dedication to innovation and customer satisfaction, STARK Spannsysteme GmbH consistently delivers reliable and efficient clamping systems tailored to the evolving needs of the manufacturing sector.

|

|

HILMA.UC 125 machine viseConcentric, modular, flexible, precise, jaw width 125The HILMA.UC125 universal clamping system is suitable for almost unlimited clamping tasks. Small workpieces as well as large plates can be clamped and machined with high degrees of freedom. Even when production requirements change, there is no need to invest in new clamping devices. The HILMA.UC universal clamping system can be adapted to different workpiece geometries in just a few steps. Special features of the HILMA.UC 125 machine vise family:

|

|

Precise Clamping

|

Modular & Flexible

|