B1.460

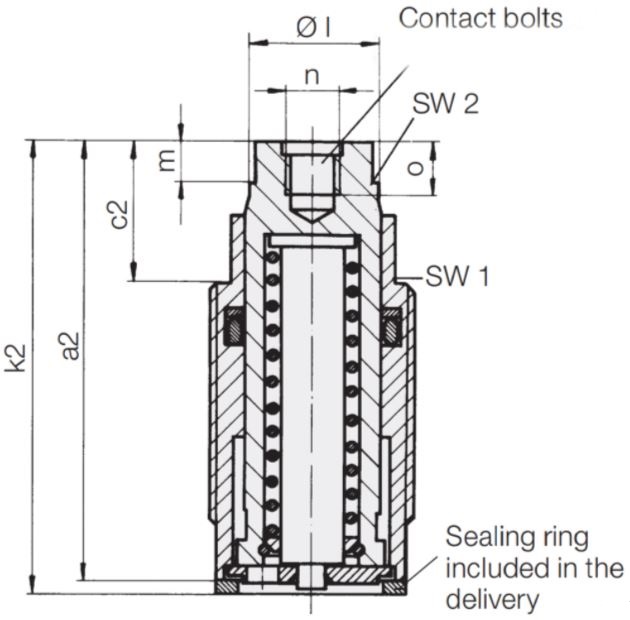

Threaded-Body Cylinders – Tapped Plunger

7250 psi max, single acting

Features

- available in five body diameters, with inch or metric threads

- with a choice of tapped plunger (shown here), radius plunger, or swivel plunger

- clamping force at 7250 psi

- long plunger guide ensures excellent reliability and durability.

Check Price & Availability on CarrLane.com

Versatile push clamps that provide considerable force in a small size. These small clamps can be placed very close together, especially when manifold mounted. Clamps can be screwed all the way down to their hex flats, or installed at partial depth. Long plunger guide ensures excellent reliability and durability.

Available in five body diameters, with inch or metric threads, with a choice of tapped plunger (shown here), radius plunger, or swivel plunger. Clamping force at 7250 psi:

1280 lbs

2270 lbs

3530 lbs

5530 lbs

9000 lbs

Clamping Action

Applying fluid pressure advances the plunger. Spring return.

Design Considerations

Threaded-Body Push Clamps have a positive stroke stop in extended position, but not in retracted position. Do place a load on the plunger while retracted.

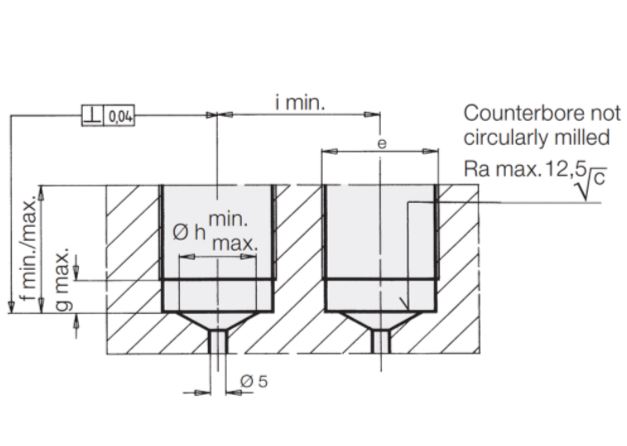

Mounting & Fluid Supply

Several possible mounting methods: 1) install clamp directly into a flat-bottom tapped hole in the fixture – see drawings for hole-preparation instructions; 2) install clamp into a Mounting Block; 3) install clamp into a Feeder Cap and mount through a fixture wall (secure with a Jam Nut or Mounting Flange). In all cases, hydraulic sealing is accomplished by a Sealing Washer (furnished) placed directly underneath the clamp. Tighten clamp to recommended seating torque.

Fluid passages must be drilled as shown in the drawings. Do not use NPT fittings.