Swing Sink Clamping Element

Double-acting

Features

- ideal power transmission

- position monitoring, emergency hand operation and overload protection combine to ensure high functional safety

- compensates for large clamping edge tolerances (± 1.5 mm)

- no colliding edges, smooth die positioning

- optimum use of ram and bed surfaces

- die clamping in barely accessible positions

- Swing sink clamping elements troubleshooting

The Roemheld Swing Clamp is part of the Quick Die Change solutions we offer to help speed up your die change and help accomplish JIT (Just in Time) Manufacturing. To survive in today’s market, manufacturers are reducing inventory costs by running smaller batch sizes and making shorter production runs. The double acting swing sink clamp with a 90° swing angle helps that.

With clamping forces from 6 tons to 41 tons, the clamp extends from below the bolster surface to clamp in a slotted pocket. This leaves the bolster clear during the die change. To help ensure safety, inductive proximity switches monitor the unclamp, change-over and clamp positions. The swing mechanism is protected with a spring-loaded overload detent and equipped with manual emergency operation. The piston is guided by a control bolt so that during the stroke movement a rotation of 45° is effected. Tie rod, piston and swing mechanism are hardened.

As of April 2020, The Hilma Roemheld range of die clamping systems has been extended with two new larger sizes of their swing sink clamps. The new clamps will provide 25 tons and 41 tons of force per cylinder. These internal clamps can be directly mounted onto the press bed or ram when die clamping is inaccessible.

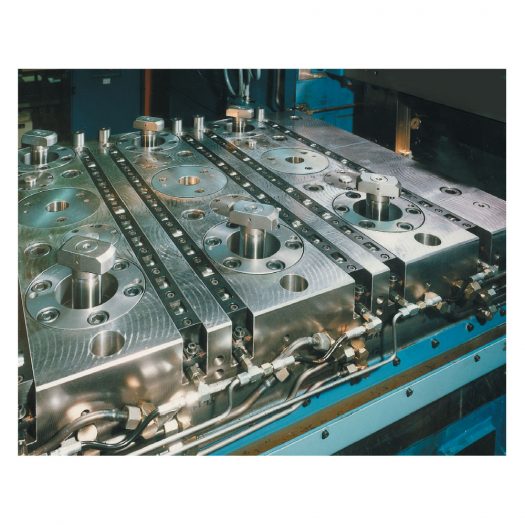

Swing sink clamps fastened in a double column press. The tie rod is extended (swing position). Easy feeding of dies by hydraulic roller bars installed in the T-slots and latereal stops.