B 1.891

Swing Clamps – 2 Series

7250 psi max

Features

- 1 size available

- available counterclockwise swing motion or without swing motion

- single-acting and double-acting

- operating pressure 350 bar

- sturdy swing mechanism

- metallic wiper option

Check Price & Availability on CarrLane.com

Swing Clamps utilize a sturdy helical-cam mechanism to swing the clamping arm clear for unrestricted loading. The threaded-cartridge Swing Clamps shown here provide considerable clamping force in a small size, because they can operate at a full 7250 psi with any standard clamping arm. These Swing Clamps incorporate our unique safety-clutch mechanism. If the clamping arm strikes an unexpected object during its swing, the clutch disengages to avoid damaging the object or the clamp’s helical-cam mechanism. Clamping arm can be mounted to start its 90° swing from any position within 360°. Threaded-cartridge Swing Clamps are designed specifically for space-saving manifold mounting.

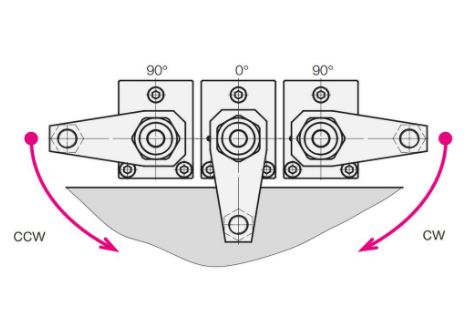

Available in one clamp size, single acting and double acting, with a choice of clockwise, counterclockwise, or zero° swing. Available with 45° and 60° swing angles by special order. The single-acting version has a slightly longer body due to the return-spring mechanism. Clamping force at 7250 psi for single-acting clamps with a standard clamping arm: 830 lbs (2 series)

Clamping Action

Swing Clamps are pull-type cylinders where part of the total stroke is used to swing the piston, and the remaining stroke is available as the clamping range. Applying fluid pressure swings arm 90° over workpiece then clamps down. The single-acting version shown here has a fast, totally dependable spring return that lifts the arm, then swings it back 90° for loading/unloading.

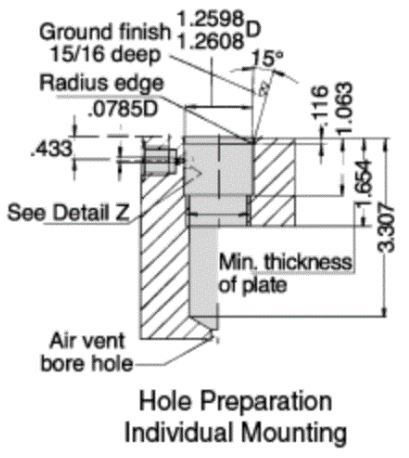

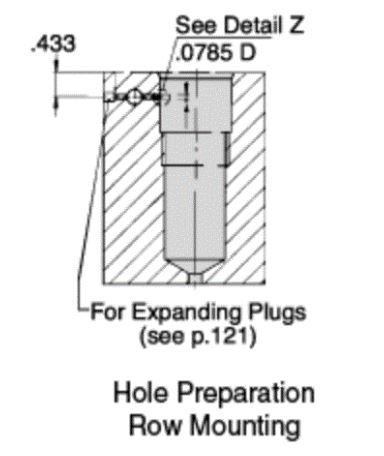

Mounting & Fluid Supply

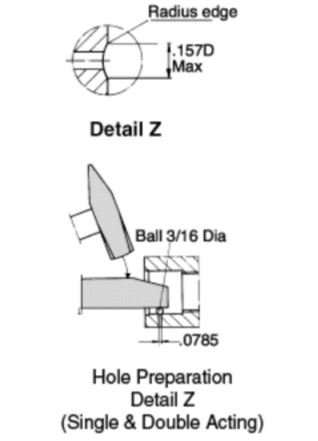

Screw clamp into fixture up to the body hex. Threaded-cartridge clamps have O-ring seals on their outside diameter, so they require a precision mounting hole. Carefully follow hole-preparation instructions in the drawings. Round the sharp edge on the upper fluid passage with a 3/16″ dia ball as shown in Detail Z of the drawings (otherwise the lower O-ring can be damaged when the clamp is screwed in). Check for burrs with finger before installing. Fluid passages must be drilled exactly as shown in the drawings. Do not use NPT fittings.

Clamping Arm

Order clamping arm separately – see clamping accessories. Standard Clamping Arms can be used at pressures up to 7250 psi on these clamps. Standard clamping arm (7250 psi max), gooseneck clamping arm (5000 psi max) & short clamping arm (7250 psi max) available for this specific swing clamp.