Block Cylinders w/ Magnetic Sensors for Position Monitoring

B1.554

Block Cylinders w/ Magnetic Sensors for Position Monitoring

double acting, optional manifold mounting

Features

- available in five sizes

- with a choice of three stroke lengths up to 100mm

- push force at 5000 psi

- high forces available

- easy to mount, horizontally or vertically

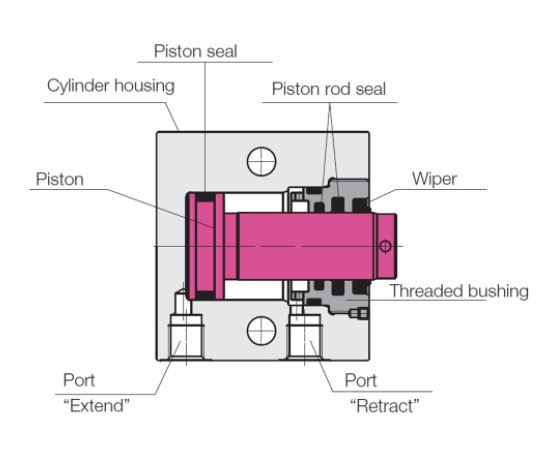

These specific double-acting Block Cylinders have an aluminum body and a magnetic piston, to allow using Magnetic Sensors for position monitoring (order Magnetic Sensors and Connecting Cables separately). Compact design with many applications. Easy to mount on flat surfaces, horizontally or vertically. Excellent for pressing and assembly operations, with high forces available. Can also be used for pulling, by reversing the A and B ports.

Available in five sizes, each with a choice of three stroke lengths up to 100mm. Push force at 5000 psi:

3840 Lbs

6320 Lbs

9890 Lbs

15400 Lbs

24500 Lbs

Clamping Action

Applying fluid pressure to the A port advances the plunger. Switching pressure to the B port positively retracts the plunger.

Design Considerations

Since operating pressure is limited to 5000 psi, flow rate to the cylinder must be restricted with a Flow Control Valve in both the advance and return line to prevent temporary pressure spikes. Each line must have free flow out of the cylinder. Aluminum Block Cylinders are not suitable for blanking or punching operations. Nearby steel structures can influence the the magnetic field of the piston, thereby affecting the switching points. This can usually be compensated by moving the Magnetic Sensors slightly. Covers are required to keep away ferritic chips.

Mounting & Fluid Supply

Several possible mounting methods: 1) insert four socket-head cap screws from the plunger end, through the four counterbored holes parallel to the plunger; 2) insert four socket-head cap screws from the bottom end, through the four counterbored holes parallel to the plunger; 3) insert two socket-head cap screws through the two broad-side holes perpendicular to the plunger. Method 3 requires that the Block Cylinder be backed up for pressures over 2300 psi by a rectangular strip or dowel pins with a height at least 1/3 of the B dimension.

Two 1/4″ BSPP ports (largest size has 1/2″ BSPP ports). Because of the aluminum body, use soft-seal port fittings CLR-9208-132-F (CLR-9216-021-F for 1/2″ BSPP). Soft-seal fittings are limited to 5000 psi. Do not use NPT fittings.

Magnetic Sensors

These electronic sensors detect the magnetic field of the magnetic piston. Switching points can be easily adjusted by sliding the sensors in the slots. Magnetic Sensors offer several advantages over conventional reed switches, including indifference to shock and vibration, a bounce-free output signal, only one switching point, wear resistance, protection against reverse battery, and protection against short circuits. Voltage 10-30 VDC. Choice of PNP or NPN output signal. Operating temperatures up to 200°.F.

Optional Viton Seals

For high-temperature applications (212° to 300° F), we offer Viton seals in all sizes. Viton seals have a slightly shorter service life. Please contact factory for more information.

| Document Title |

Language |

File Type |