Helping Separate and Connect Hydraulic Lines

Couplings

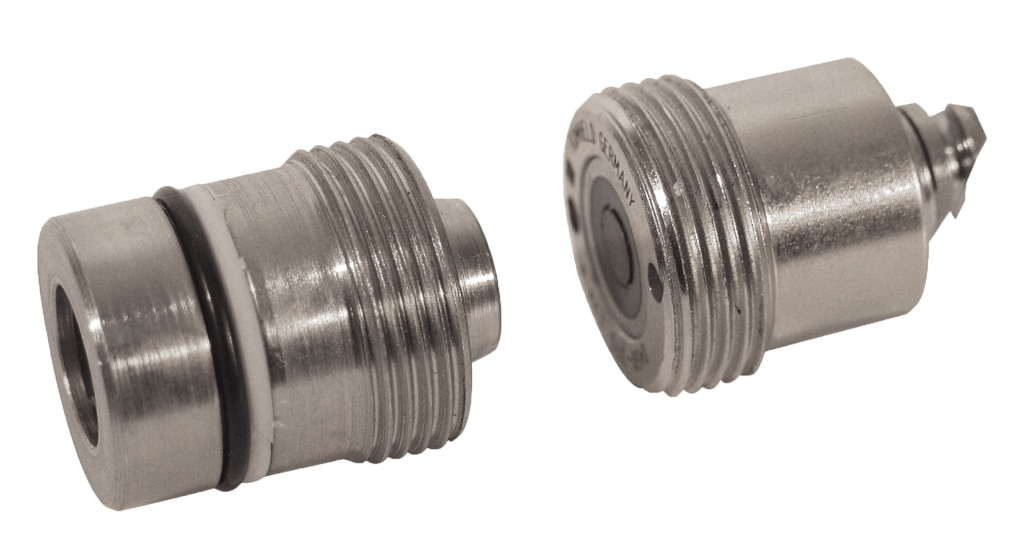

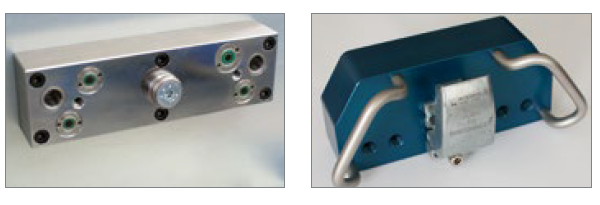

Single coupling elements and multi-couplings for transmission of hydraulic oil, compressed air and vacuum. See below for an application example of two couplers coming together showing how the oil would go through.

|

Built-in type and threaded-body type

|

ND 3, ND 5, ND 8, ND 12, max. operating pressure up to 500 bar Coupling mechanism and coupling nipple are provided with axial seals. This results in a very short coupling stroke as well as a smooth front face of the coupling mechanism and thereby only little area of attack by dirt and swarf. The build-in types are designed for mounting in plates and are particularly suitable for the use in multi-couplings (see data sheet F9.440). The threaded-body types can be screwed in directly in the fixture body and are therefore optimum line connections between two components as e.g. basic fixture and changing fixture. |

|

Threaded Coupling Elements

|

Max. operating pressure 500 bar Coupling mechanism and coupling nipple are provided with axial seals. This results in a very short coupling stroke as well as a smooth front face of the coupling mechanism and thereby only little area of attack by dirt and swarf. The build-in types are designed for mounting in plates and are particularly suitable for the use in multi-couplings (see data sheet F9.440). The threaded-body types can be screwed in directly in the fixture body and are therefore optimum line connections between two components as e.g. basic fixture and changing fixture. |

|

Multi-Couplings

|

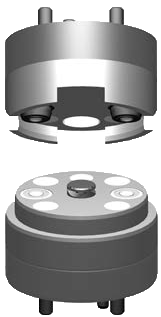

Depressurised coupling and coupling against system pressure max. operating pressure 300 bar The multi-coupling is a modification of the threaded coupling elements as per data sheet F 9.430. It is composed by two components, the nipple carrier and the coupling carrier. The advantage of the coupling carrier is the fact that its face is flush in uncoupled condition, thereby it can be easily cleaned by means of the integrated blast air system. With these coupling elements coupling or uncoupling of lines can be effected against system pressure or depressurized. The coupling and nipple carrier can be equipped or retrofitted by an additional line (ND 3) for the passage of air, water or hydraulic oil (single coupling elements see data sheet F 9.428). |

|

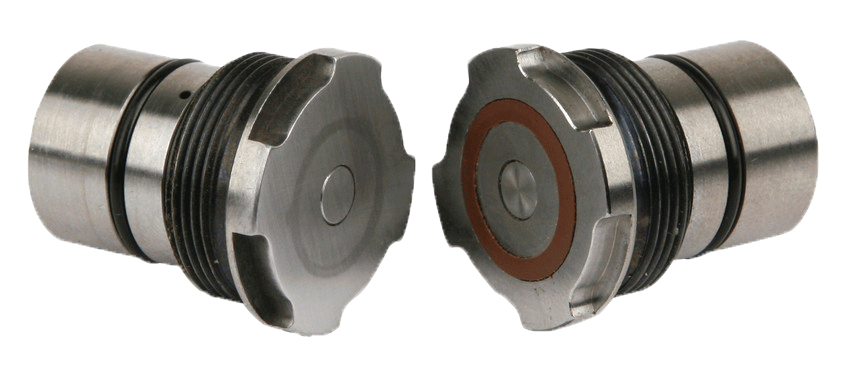

Coupling Elements without Coupling Stroke

|

Threaded-body type, ND 4, depressurised coupling, max. operating pressure 200 bar These automatically closing couplings have a flat surface and do not have protruding elements for sealing. Therefore exact positioning is not required and a radial positioning misalignment of up to 2 mm is admitted. Cleaning of the coupling surfaces is easily possible due to the flat surfaces. |

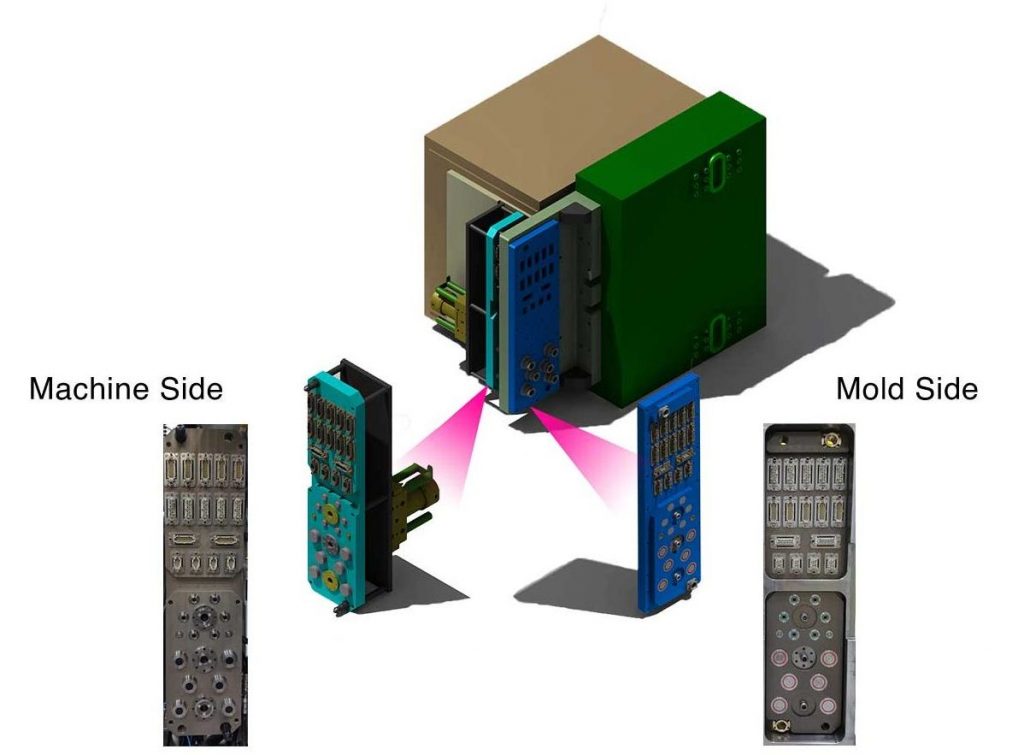

Couplers for Molds help you easily connect oil, coolant or air from machine to mold, they can be used on Injection Mold Machines to pass fluids from the machine to the mold.

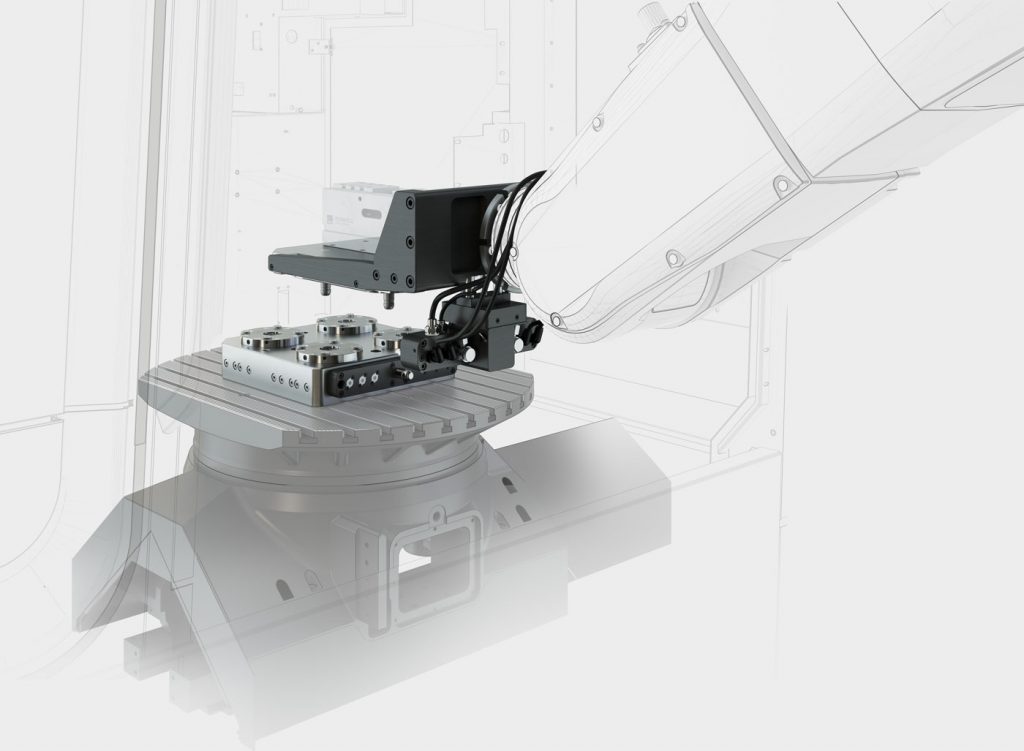

Couplers can be used on machining centers to pass oil and coolant from the machine to the fixture. The connection is made when the pallet changer lowers the plate onto the table. Another option is to have a drive unit make the connections.

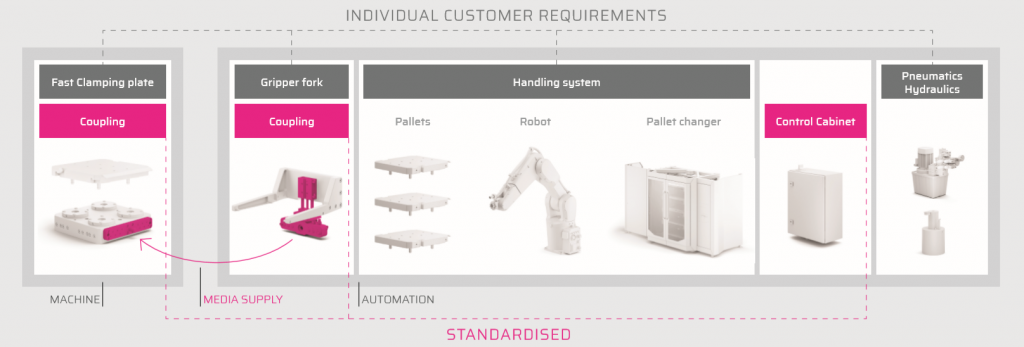

Reduced implementation time & costs thanks to standardized coupling unit and flexible modular system.

Multimedia coupling (electrical + pneumatic)

The STARK media coupling with a combination of pneumatic and electric couplings was specially developed for automation. The coupling can be used in combination with all STARK zero point clamping systems. An automatically extending, integrated cleaning nozzle keeps the contacts clean.

Multimedia coupling (hydraulic + pneumatic)

If you need to connect several lines on a repetitive basis, we offer a multimedia coupling for just this purpose. The unit can be configured based on your individual requirements including how many lines and what medium you need to connect – Air, Oil, coolant etc. By using the Stark EasyClick clamp, the plates are connected, and the lines are free to flow. Once the work is done, the lines are depressurized, and the unit is removed with the push of a button.

Videos I Download Roemheld Product Summary I Catalog