WS5.4502

MCP/Z-Series 5-Axis Concentric Manual Vise

concentric clamping, mechanical operation

Features

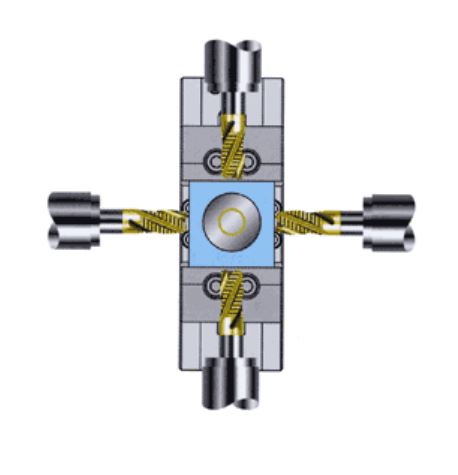

- patented sliding-jaw segment design

- incorporated with our precision self-centering mechanism

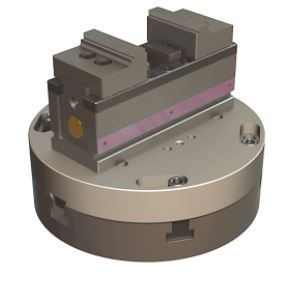

- two moving jaws that provide clamping at the exact center of the rotary table

- available in the four sizes shown below

- optimal features to allow unrestricted tool access for multiple-side machining

Check Price & Availability on CarrLane.com

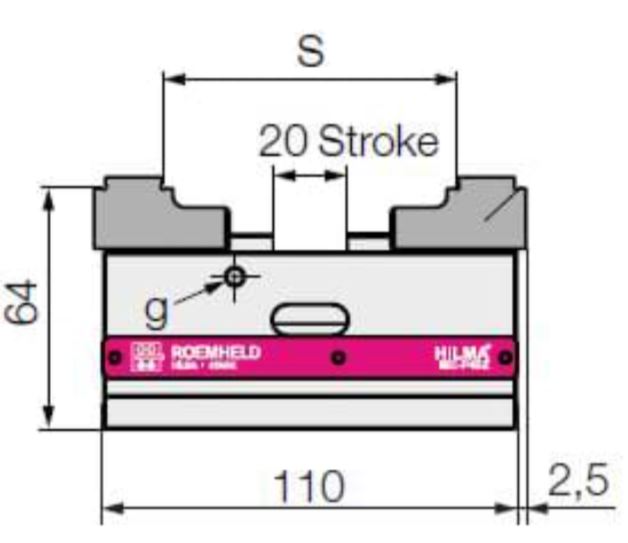

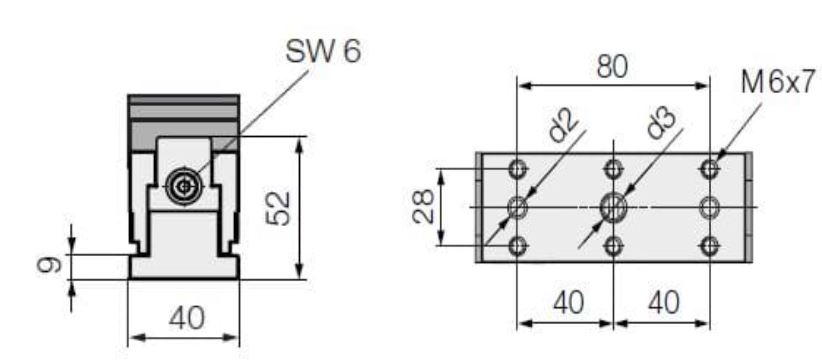

MCP-series 5-axis vises have optimal features to allow unrestricted tool access for multiple-side machining. Z-series MCP vises are dimensionally similar to the standard fixed-jaw version, but incorporate our precision self-centering mechanism. Concentric vises have two moving jaws that provide clamping at the exact center of the rotary table. Available in the four sizes shown below, with the following jaw widths:

40mm

60mm

100mm

125mm

60mm

100mm

125mm

The MCP series is a further refinement of our high-precision MC vise series. These new vises combine a very compact, fully enclosed design with a patented sliding-jaw segment design. Thanks to the adjusting spindle arranged in the upper part of the housing, deformation in the base during clamping is reduced to a minimum, providing high rigidity of the entire workholding system. The patented segment design ensures a high degree of precision and stability, reducing guiding clearance to nearly zero.

Mounting on Quintus 1 Riser

Due to its small size, the MC40 vise must first be mounted on a Quintus Vise Adaptor Plate (CL-130-01-QRFP), which is then mounted on the Quintus 1 riser. To locate the vise on the adaptor plate, use two Fixture Locating Pins, a round pin for zero-point centering and a diamond pin for single-axis centering. To fasten the vise, use six M6 x 30mm socket-head cap screws inserted through the plate from below. Next, install a Quintus 1 pull-down bolt in the adaptor plate’s M10 bottom center hole. To locate the adaptor plate, the Quintus 1 riser utilizes its two integral locating pins, a round pin for zero-point centering and a diamond pin for single-axis centering, which fit into the two 10mm locating holes underneath the plate. Turning the Quintus mechanism exerts 2700 lbs of force on the pull-down bolt. See Related Products below for mounting accessories.

Mounting on a Vise Adaptor Plate

Vise Adaptor Plate mounted directly on a rotary table. To locate the vise, use two Fixture Locating Pins, a round pin for zero-point centering and a diamond pin for single-axis centering. To fasten the vise, use six M6 x 30mm socket-head cap screws inserted through the plate from below. See Related Products below for mounting accessories.

Unique design allows clear tool access to five-out-of-six workpiece sides.