B1.9470

Threaded-Body Work Supports – Fluid Advanced

for Low-Pressure Hydraulic Systems

Features

- single-acting

- fluid advanced

-

manifold mounting capability allows space-saving low-height installation

-

highly corrosion resistant with a stainless steel plunger and internal components

-

metallic wiper and FKM wiper together provide excellent protection against dirt and coolant entry

-

hardened contact bolt furnished

-

available in four sizes

-

load capacities at 1000 psi:

Check Price & Availability on CarrLane.com

This series of threaded-body work supports provide considerable load capacity at lower hydraulic pressures, allowing direct connection to the low-pressure hydraulic system of a machine tool.

Work Supports automatically adjust to the proper height for supporting a workpiece, then lock securely to become fixed rests. Fluid-advanced Work Supports provide extra loading clearance and are ideal for workpieces that are too light to depress a spring-loaded plunger. These Threaded-Body Work Supports are amazingly compact. Manifold mounting capability allows space-saving low-height installation. Highly corrosion resistant with a stainless steel plunger and internal components. Metallic wiper and FKM wiper together provide excellent protection against dirt and coolant entry. Hardened contact bolt furnished.

Available in four sizes, with the following load capacities at 1000 psi:

670 Lbs

900 Lbs

1200 Lbs

2200 Lbs

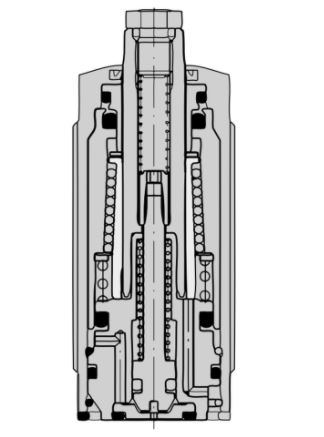

Support Action (Fluid Advanced)

Plunger is normally retracted for clear workpiece loading and unloading. Applying fluid pressure gently advances the plunger to the workpiece, where it contacts with light spring force. As fluid pressure increases, the precision sleeve grips the plunger, locking it securely. The plunger retracts again when pressure is released. Locking height is repeatable within +/-.0002″. Such excellent repeatability is possible because of two design features: 1) a precision sliding-fit pressure sleeve holds the plunger absolutely vertical even while unlocked, avoiding any inaccuracy due to locking a tilted plunger, and 2) locking force is entirely radial, so the plunger remains absolutely stationary during the locking process.

Design Considerations

Do not use the plunger to lift loads, or support side loads. The support plunger must always be protected against penetration of contaminants by a contact bolt (furnished). When supporting underneath a clamp, use a Sequence Valve to delay clamping until the Work Support has reached sufficient load capacity to resist the clamping force. Support load capacity should be at least 2 times clamping force at all times, to resist not only static clamping force, but also dynamic forces due to clamping-arm momentum and machining forces.

Mounting & Fluid Supply

|

|

|

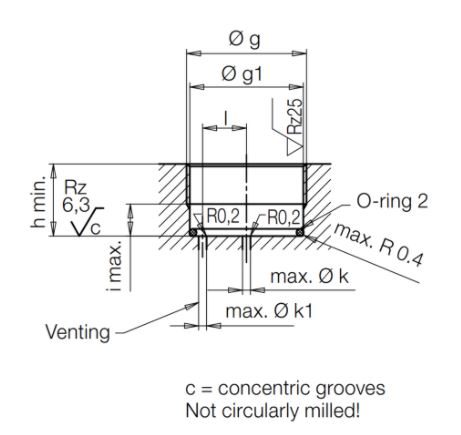

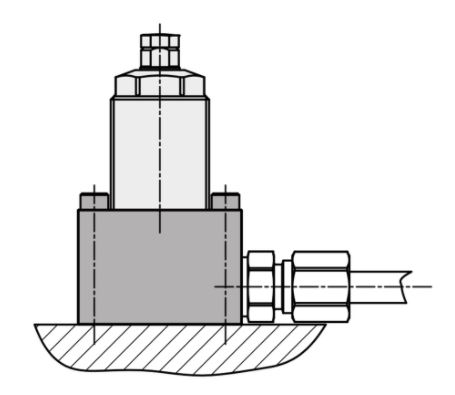

| Hole Preparation | Manifold Mounting | Optional Mounting Block |

Install Work Support directly into a flat-bottom tapped hole in the fixture – see drawings for hole-preparation instructions. Alternatively, inch-size Work Supports can be installed in a Mounting Base. In both cases, hydraulic sealing is accomplished by a Sealing Washer (furnished) placed directly underneath the support. Tighten to the recommended seating torque. Fluid passages must be drilled as shown in the drawings. Do not use NPT fittings.

A specially designed metallic wiper edge effectively protects the FKM plunger wiper from hot, abrasive chips.