- Reduce setup times up to 90% => no more indicating

- Lights out or unmanned production is possible

- Maximize spindle up time => means you can increase throughput without having to buy more machines.

- Reduced setup time and costs = increased competitiveness

- Standardized set-up processes => can use ZPS across the manufacturing floor from machining to QC to assembly and welding

- Increased part quality and less scrap

- Batches can be interrupted at any time to accommodate a rush order.

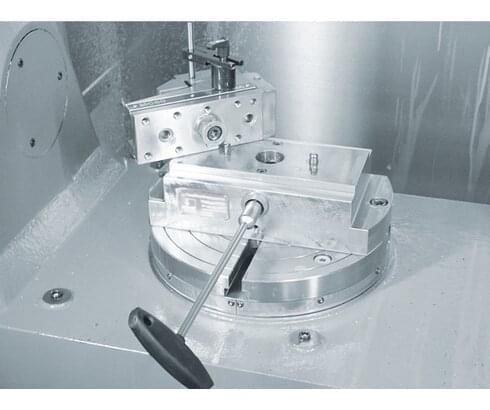

Economical entry-level solution from STARK, offering the highest quality on the market.

- Fast closing plate made of steel ground on both sides with fixing holes for different groove distances (63, 100 and 125 mm)

- Zero Point clamping system is clamped mechanically with spring force and released hydraulically/pneumatically

- Application on 3/4/5-axis machines for all common machining operations such as milling, grinding, and eroding.

Download Flyer >

Our Application Engineers in North America are available to collaborate on solutions that address your unique challenges and leverage our expertise and capabilities to co-create custom yet cost-effective solutions from our standard components.

Machining

- Aluminum and plastic machining

- Price-conscious entry-level models

- Easy handling

- Maintaining the highest accuracy and maximum process reliability

Recommended Products

Gripper

- Price-conscious entry-level models

- Easy handling

- Maintaining the highest accuracy and maximum process reliability

Recommended Products

- STARK.gripper

- Fast Clamping Plates

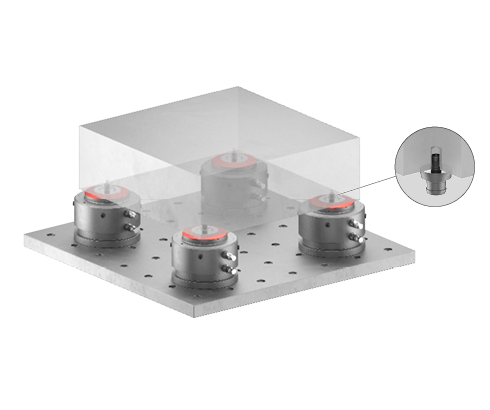

Direct Clamping

- Workpiece processing with zero-point accuracy using several machines

- 5-side accessibility

- Use existing threads on the workpiece

- Zero-point flexibility

- Compensation options for tolerances and temperature variation

Recommended Products

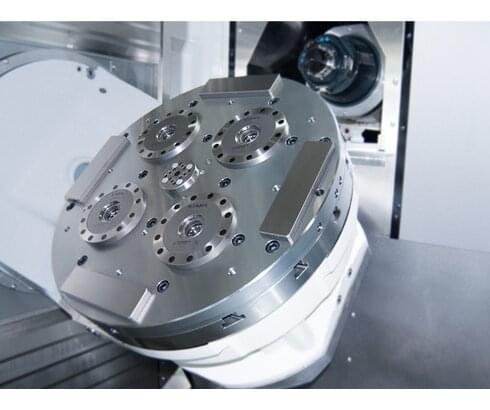

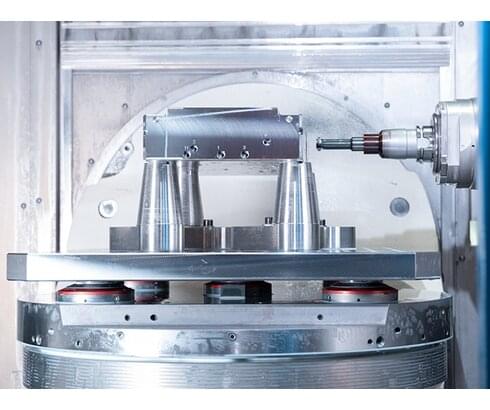

Turning & Milling

- High machining forces

- 5-axis processing

- Casting machining

- Machining of large workpieces

- Ideal for high-performance machining centers

- Maximum safety in milling and turning applications

- Integrated media feed-through

Recommended Products

Welding & Assembly

- Standard to Industry 4.0 applications

- Automation of welding systems

- Compensation options for tolerances and temperature variation

- Flexibility options in the area: framer, geo-gripper, geo-skit

- Simple device change in assembly and handling technology

Recommended Products

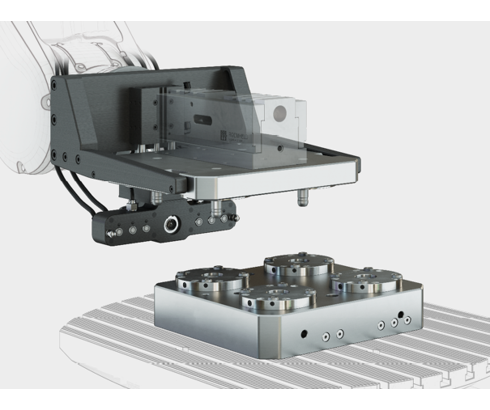

Automation

- High change cycles

- Long maintenance intervals

- Short changeover times

- Innovative self-cleaning function on the zero-point clamping system

- Most modern & reliable query technology

- Integrated solution for process lines, machining, cleaning, assembly, measuring eg: cylinder head production

- Solution for pallet handling eg: STARK.gripper

Recommended Products

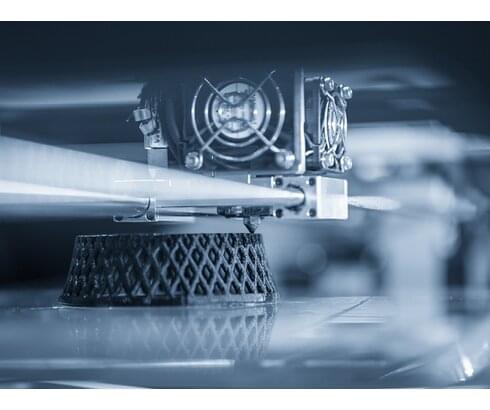

Additive Manufacturing

- Manufacturing at high temperatures

- Interface optimization for various processing steps (e.g. intermediate measurements)

- Economical from batch size 1 to series production

- Strong customization of products

- Automation

Recommended Products

A zero-point clamping system by ROEMHELD Stark is a quick change system that allows you to clamp parts with accuracy, speed, and flexibility using retractable nipples and fast-closing clamps. It allows you to connect fixtures to machine tables in seconds with precision. Existing fixtures can be easily adapted to the system, which allows for fast payback, longer fixture life, and highly accurate positioning and repeatability.

What is the accuracy of Zero-Point Clamping?

ROEMHELD Stark’s Zero-Point Systems reach an accuracy of up to 0.003 mm and can achieve a clamping force of up to 52,000 N. They can be operated hydraulically, pneumatically, electrically, or mechanically.

What is the difference between a conventional setup and a Zero-Point system setup?

With a conventional setup, you must position the vise via mounting bolts, align, take measurements through a dial indicator (if the vise is not square on the table), adjust the vise if measurements are incorrect, and repeat this until you get the measurements you need. Then, you can finish tightening down your bolts.

With zero-point clamping, you can eliminate this time-consuming setup.

The zero-point gets similarly mounted on the table above, but you only do it once. Once mounted, your machine vise or fixture can be mounted directly on top of the zero-point. Now, you can drop your workpiece in and go. The zero-point does all the clamping and positioning for you, reducing setup times by up to 90%. Furthermore, if a rush order comes in you can easily interrupt what is currently being machined and later reload the part back into the machine without losing accuracy.

Do you have to use a vise or chuck with a Zero-Point System?

When it comes to zero-point workholding systems, you do not always have to use a machine vise or chuck. Our systems give the option to attach the zero-point nipple directly to the workpiece itself, either to a sacrificial material that is removed in the secondary option or by bolting it to an existing threaded hole. A clamping stud will attach directly to the part, allowing the least-intrusive fixturing possible. This utilizes a floating zero-point chuck that “finds” the position of the fourth support, effectively eliminating the distortion that commonly occurs when clamping thin-wall parts.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.