Case Study from

Römheld GmbH Friedrichshütte

By Admin

The requirements for using therapy beds in school are particularly high right now: they enable aspiring masseurs and physiotherapists to work comfortably and painlessly – and also endure rough use from the students everyday work.

For this reason, beds with a hydraulic drive are often used in physiotherapy training to give height adjustment.

For this reason, beds with a hydraulic drive are often used in physiotherapy training to give height adjustment.

“Treatment couches are heavily used during training,” says Jutta Gissler, Managing Director of Özpinar Therapiegeräte GmbH from Biberach in the Black Forest, “which is why I recommend the hydraulic drive: so that the most important work tool is resilient and can withstand incorrect operation.” For a physiological, back-friendly treatment working and the health of the therapist, the correct height of the patient is crucial, which is why the drive for adjusting the bed is a highly stressed component. “That is why schools and training companies in particular are asking for treatment tables with hydraulic height adjustment, because they are particularly robust,” explains the managing director. Alexander Schul, Head of Assembly and Drive Technology at ROEMHELD, confirms

:

Hydraulics are resilient

Compared to electric drives, hydraulic actuators are particularly durable and almost maintenance-free. In addition, no power connections are required, so that there are no annoying cables that can quickly become a trip hazard in practices and schools without floor sockets. “Some therapists and treatment methods also prefer hydraulics because they are not whirring, but are absolutely silent and, in addition, no energy flows can disrupt the treatment,” summarizes Gissler. Around a third of the loungers sold by Özpinar have

hydraulic drives, the rest are operated electrically.

Wide range up to complete practice facilities

In addition to self-employed physiotherapists and naturopaths, the customers of treatment tables with hydraulic drives are often used by doctors for schools and clinics. Jutta Gissler, who took over Özpinar in 2006, has since developed the company into a practice supplier with 27 employees and 2012 sales of approx. € 3.3 million. The company has around 1,450 therapeutic items in its online shop, which are delivered with its own fleet throughout Germany. Özpinar works with partners in Switzerland and Austria.

The range extends to complete practice facilities that are installed and assembled by our own technicians on site. With a revenue share of sixty to seventy percent, the focus is on the steadily growing company, which continues to expand in 2013 with the construction of new administration and production facilities in the immediate vicinity of the current location.

Durable quality and attractive prices

According to Gissler, Özpinar’s secret of success is “long-lasting and high quality at attractive prices and good and fast service. Our standard ‘Select’ model is ready for dispatch the day after the order is placed. ”There is also a wide selection that offers customers numerous options for configuring a product according to their own ideas: there are up to thirty variants for the loungers alone are available with around seventy different leather covers.

Improvements can be implemented quickly

Özpinar can only respond so quickly to the individual wishes of its customers because most of the production takes place within the facility; from product development to metalworking, welding and sewing to upholstery and assembly all are departments in-house, only the powder coating of the metal frames is done by a partner. Gissler also sees advantages in the high level of vertical integration for the quality of their products: “This means that we always have an eye on all production steps and can implement improvements quickly.”

This was also the case with the hydraulic pumps that Özpinar used when Jutta Gissler took over the company in 2006: “The stroke reacted too heavily depending on the load, and I also found that the oil gurgled too loudly.” Open ears: After several discussions, the supplier smoothed different surfaces on the piston and pump of the hydraulic drive, changed individual contours and adjusted the flow control valve so that the stroke movement is now smoother and the oil flows silently.

Hydraulics with many options

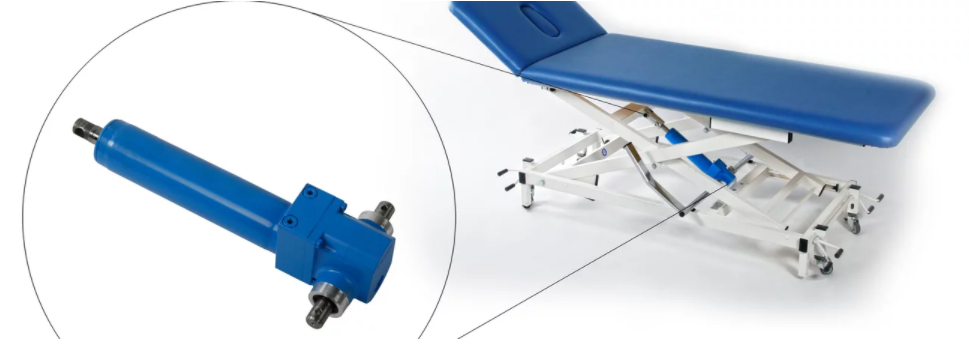

The hydraulic drive “RH 1250” from ROEMHELD used by Özpinar with a stroke of 200 mm or 250 mm consists of an oil pressure piston, which is encapsulated in a compact and maintenance-free aluminum housing made of stainless steel. It is insensitive to corrosion, cleaning agents and disinfectants. Different equipment versions are available with stroke lengths between 140 mm and 250 mm, for actuation via foot or hand lever, with pressure or rotary release and optionally for fork or flange mounting. The “RH 1250” “made in Germany” is manufactured at ROEMHELD’s headquarters in Laubach, Hesse. Further production sites are located in Hilchenbach near Siegen and in Austrian Götzis.

In addition to drive technology, the product range of the world-renowned clamping technology specialist ROEMHELD includes industrial manufacturing, assembly and clamping technology for the manufacturing industry. 450 employees achieved sales of around 88 million euros in 2012. The market leader is represented by sales and service companies in more than 50 countries on all continents.

Loungers also serve as a desk

The “Robusta” couch model with an extended head section is often used in schools and academies, which, like the foot section, can be infinitely adjusted using gas pressure springs. Thanks to a specially shaped footrest, the lying surface can not only be operated from the foot side as usual, but just as easily from the two long sides. The subject of “stability” is particularly important to those responsible, says Gissler: “Sometimes the pupils sit or stand on the ‘Robusta’ loungers, so I’m glad that they live up to their name.” Because care and maintenance are low the cleaning staff and the caretakers who are often responsible for maintenance are also satisfied. And “Robusta” is also popular with the schoolchildren, as the manager experienced during customer visits: