QUICK MOLD CHANGES

M-TECS Magnetic Clamping Technology

Clamps in seconds. Hot mold changes in minutes.

|

|

Is Quick Mold or Die Change right for your application?Download our workbook to guide you through the selection process.

|

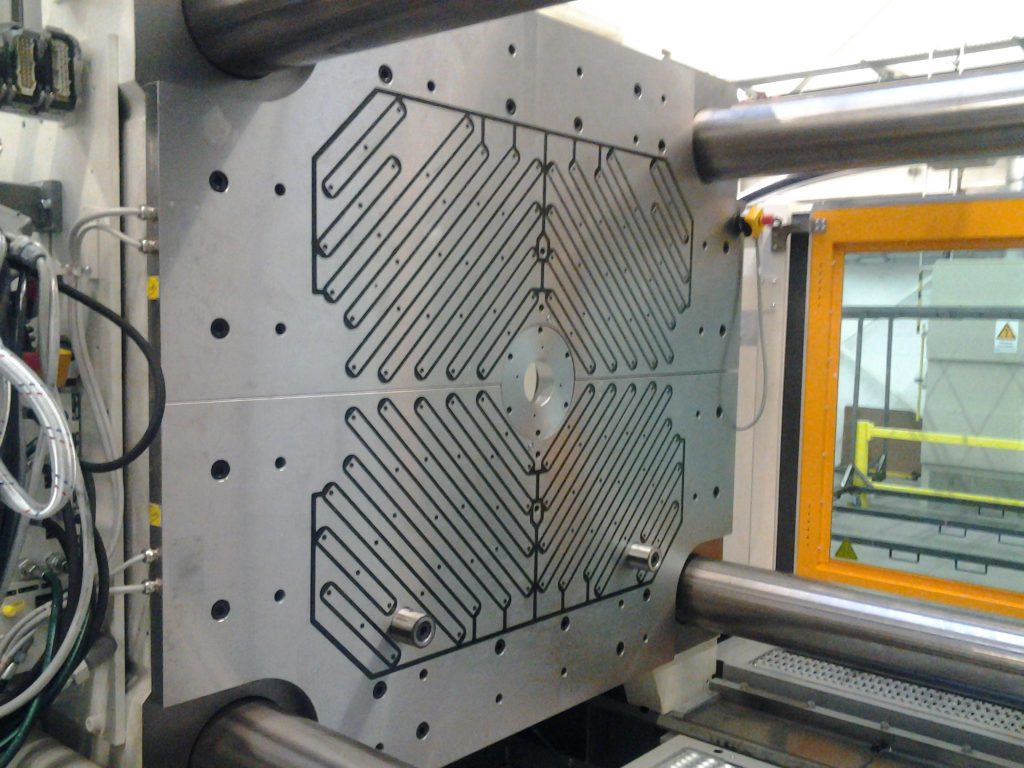

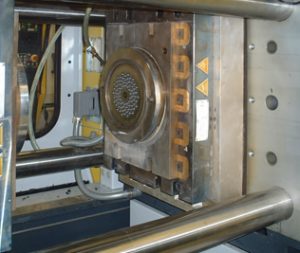

ApplicationsROEMHELD provides RIVI M-TECS magnetic clamping plates for different industry sectors, including thermoplastics, elastomers, duroplastics, polyurethane, die casting, and metal forming. The systems include square or long pole technology providing M-TECS power concentration and are resistant to high temperatures up to 464°F help you achieve a Single-Minute Exchange of Die (SMED). |

|

|

Safe in Power FailureWith Rivi Magnetics magnetic clamping systems, the molds are magnetically clamped or unclamped at the touch of a button within a few seconds. Since permanent magnets generate the force of the magnetic clamping plates, electric clamping is only required to magnetize the plates. The magnetic clamping plates are de-energized in clamped condition and thus absolutely safe in a power failure. The complete clamping cycle is monitored by different sensors, thus guaranteeing reliable mold clamping. All Rivi Magnetics magnetic clamping systems carry the CE mark. |

Benefits

|

|

M-TECS Magnetic Clamping Technology

9.1132 | METALRivi Magnetic Clamping Systems M-TECS M for temperatures up to 248 °F |

9.1134 | PLASTICRivi Magnetic Clamping Systems M-TECS P for temperatures up to 356°C |

9.1136 | RUBBERRivi Magnetic Clamping Systems M-TECS R for temperatures up to 464 °F |

9.5660 | M1C/M2CElectric Control M1C / M2Cfor Rivi magnetic clamping systems M-TECS |

90% reduction in mold changeover times

Magnetic clamping systems offer a revolutionary solution to the shortcomings of traditional mechanical and hydraulic systems in injection mold machines.

Unlike mechanical systems, which lack the ability to halt the machine in case of faults, and hydraulic systems, which are susceptible to power failures and require regular maintenance, magnetic clamping systems provide a reliable and fail-safe alternative.

The magnetic force ensures uniform clamping over the entire mold surface, particularly at the center, enhancing mold rigidity and product consistency. Mold change cycles are significantly shortened, with a remarkable 90% reduction in mold changeover times, thanks to the simplicity and efficiency of the magnetic clamping mechanism.

Additionally, the absence of moving or wearing parts eliminates the need for maintenance, offering an economic advantage over traditional systems with substantial labor and replacement costs.

The flexibility of magnetic clamping accommodates various mold sizes and shapes without the need for modifications, making it a versatile and efficient choice for injection mold machines.

Let’s Collaborate!

In addition to our magnetic clamping systems, we also offer a wide range of accessories and support services to help customers get the most out of their investments. This includes technical support, training, and on-site assistance to ensure that our customers can fully utilize our magnetic clamping systems’ capabilities.

Multi-Step Contact

Magnetics for O-Ring ProductionThe magnetic clamping systems are perfectly suited for the production of O-rings. The full surface dynamic effect enhanced the rigidity of the dies. The full-surface contact between the die and the magnetic page (magnetic heating plate) increases temperature homogeneity, which has a positive effect on production quality. Die change is a matter of just a few minutes. M-TECS magnetic plates can be fitted to existing heating plates or supplied with integral heating. |

|

Magnetics for Large MachinesM-TECS provides abundant power for large machines. A plate of 2000x1000mm (78.74″x39.37″), for instance, will yield up to 1000 kN (100 tons). The image shows a 500-ton vertical press with a machine bed 2000x1000mm (78.74×39.37″) Application temperatures up to 240°C (464°F) Upon request, this value may be either increased or reduced to suit specific requirements. |

|

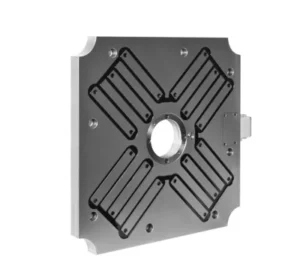

Magnetics on Small MachinesThe M-TECS concentration effect is of benefit, especially for small dies. The magnetic heating plate has a size of 300x300mm (11.81×11.81″). It is used when dies with a diameter greater than 120mm (4.72″) are clamped. Excellent power, even for the smallest application. |

|

Magnetics on Machines Without Crossbeam

The magnetic clamping systems may be universally used and are very flexible in terms of design. Horizontal and vertical installation in machines with or without cross beam, with integral heating or fitted to existing heating plates. Dies for the production of O-rings are mostly flat, and their rigidity is, in most cases, clearly enhanced when using magnetic plates. The penetration depth is only 15 – 20 mm (.59-.79 inches). Brushes or metal inserts are not impaired by the magnetic field. |

|

Magnetics on Vertical IM PressesFor vertical machines with a small heating plate, the following factors play a major role:

The M-TECS 240 system is designed with a double magnet and offers an outstanding concentration of the magnetic field thanks to the patented long pole technology. Therefore, maximum safety can be achieved by selecting a magnetic clamping system to perfectly suit the machine. |

|

Magnetics for Elastomer ProcessingWith M-TECS 240, you gain several hours at each die change. Productivity

Safety & comfort

Quality

|

|