Standard Swing Clamp – Threaded Cartridge

B1.892

Standard Swing Clamp – Threaded Cartridge

3000 to 7250 psi max

Features

- available in 4 clamp sizes

- single or double-acting

- standard fittings or manifold mounted

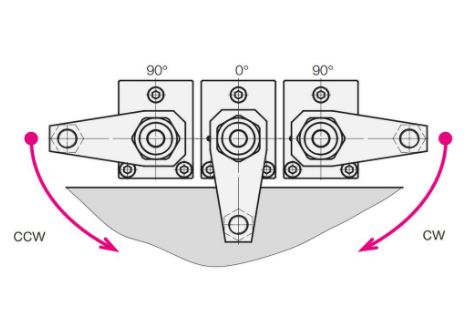

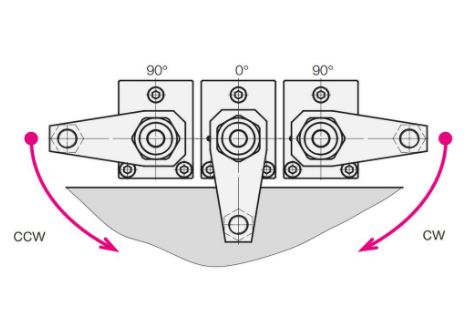

- choice of clockwise, counterclockwise, or zero° swing

- available with 45° and 60° swing angles by special order

Check Price & Availability on CarrLane.com

Swing Clamps utilize a sturdy helical-cam mechanism to swing the clamping arm clear for unrestricted loading. The Standard Swing Clamps shown here accept a wide variety of clamping arms, with maximum allowable operating pressure depending on the type of arm selected (3000 to 7250 psi max). These Swing Clamps incorporate our unique safety-clutch mechanism. If the clamping arm strikes an unexpected object during its swing, the clutch disengages to avoid damaging the object or the clamp’s helical-cam mechanism. Clamping arm can be mounted to start its 90° swing from any position within 360°. The threaded-cartridge version shown here is designed specifically for space-saving manifold mounting.

Available in three clamp sizes, single or double acting, with a choice of clockwise, counterclockwise, or zero° swing. Available with 45° and 60° swing angles by special order. Clamping force at 7250 psi for single-acting clamps with a pivoting clamping arm:

1060 Lbs (3 series)

2700 Lbs (5 series)

7300 Lbs (7 series)

Design Considerations

These Swing Clamps incorporate our unique safety-clutch mechanism. If the clamping arm strikes an unexpected object during its swing, the clutch disengages to avoid damaging the object or the clamp’s helical-cam mechanism. Do not exceed the maximum fluid flow rate in the table. For extended clamp life and proper operation of the safety clutch, a simple flow-control valve may be required if the fixture is powered by a high-flow-rate power source and only contains a few clamps. Clamping time should be at least one second.

Clamping Action

Swing Clamps are pull-type cylinders where part of the total stroke is used to swing the piston, and the remaining stroke is available as the clamping range. Applying fluid pressure swings arm 90° over workpiece then clamps down. Single-acting version has a fast, totally dependable spring return that lifts arm then swings it back 90° for loading/unloading. Optional fluid return (double acting). Available with clockwise, counterclockwise, or zero° swing.

Mounting & Fluid Supply

Screw clamp into fixture up to the body hex. Threaded-cartridge clamps have O-ring seals on their outside diameter, so they require a precision mounting hole. Carefully follow hole-preparation instructions in the drawings.

Fluid passages must be drilled exactly as shown in the drawings. Do not use NPT fittings.

Clamping Arm

Order clamping arm separately –

see clamping arm accessories. Maximum allowable operating pressure depends on the type of arm selected. Choose a Standard Clamping Arm for 3000 psi max, a Gooseneck Clamping Arm for 5000 psi max, or Pivoting Clamping Arm for 7250 psi max (requires a rear support). Longer, custom clamping arms will further reduce allowable operating pressure, inversely proportional to arm length.

| Document Title |

Language |

File Type |