Sliding Clamp

Single-Acting, Spring Return

Features

- high clamping force in combination with small size and low weight

- t-slot adapter for easy integration

- t-slot 18, 22 and 28 mm are available

- clamping force from 19 kN to 78 kN

- no need for die standardization (width and depth)

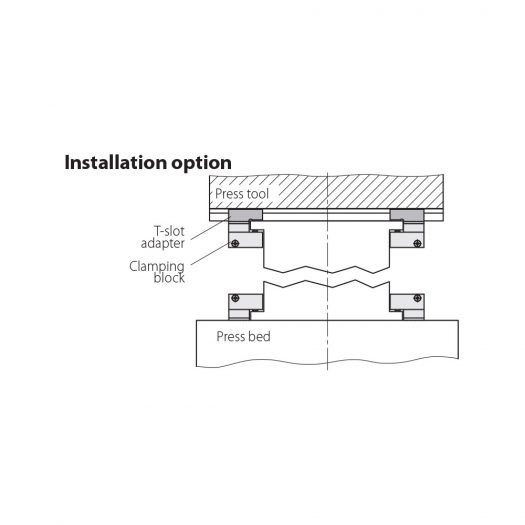

The sliding clamp is a very sturdy hydraulic clamping element, used with low space requirements for clamping and locking on machines and plants, on press bed and ram. It’s possible use is at temperatures up to a maximum of 120˚C. You can position it manually in the T-slots of the press ram or bed. It clamps on the edge of the die by applying hydraulic pressure to the piston and unclamps by spring force. The sliding clamp consists of a hydraulic clamping block which will be attached with two screws to a T-slot adapter. The clamping block can also be purchased separately to be directly mounted without a T-slot adapter.

To survive in today’s competitive worldwide market, manufacturers are reducing inventory costs by running smaller batch sizes and making shorter production runs. One way to maximize press uptime in an environment like this is to implement faster more effective die changes with the sliding clamp. The Quick Die Change System solutions helps manufacturers accomplish these goals, shortening die change time and making facilities more productive and profitable.