RM Mini Slide – Optional Position Monitoring

double acting, max. operating pressure 500 bar

Features

- 4 sizes each with 3 stroke lengths

- compact block design

- 2 fixing possibilities

- 2 connecting possibilities

- guide rods made of nitriding steel

- safety distance against squeezing of fingers

- optional position monitoring with limit switches or inductive sensors

- standard FKM-seals

- temperature range –20 – +150 °C

- maintenance-free

The RM mini slide is a compact block cylinder with 4 integrated guide rods which are also in the position to compensate side loads and moments. Threads can be provided in the front block for fixing of the working loads or tools (see page 4). To avoid a possible point of squeezing between the front block and the cylinder the safety distance of 25 mm as per DIN EN 349 is maintained. The RM mini slides can certainly be delivered equipped with position monitoring by limit switches or inductive sensors.

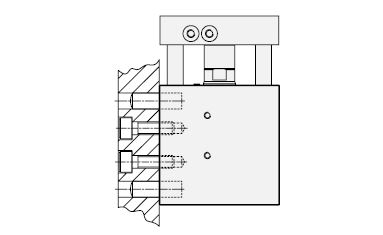

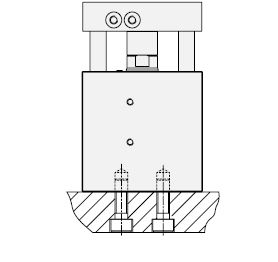

Fixing Possibilities

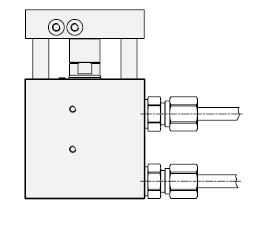

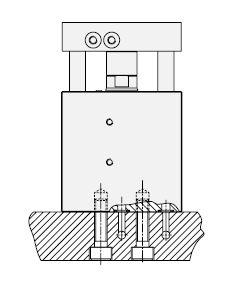

Connecting Possibilities

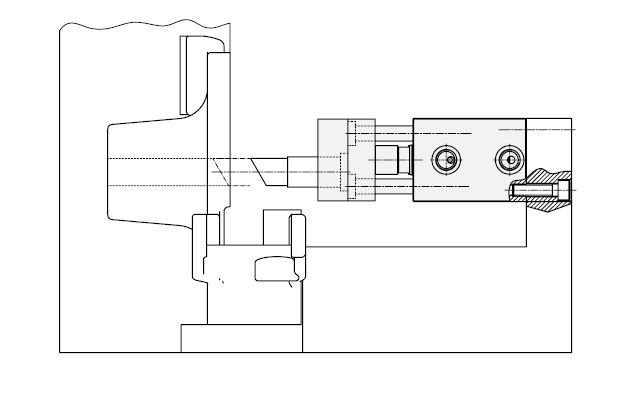

Application example for deburring tools

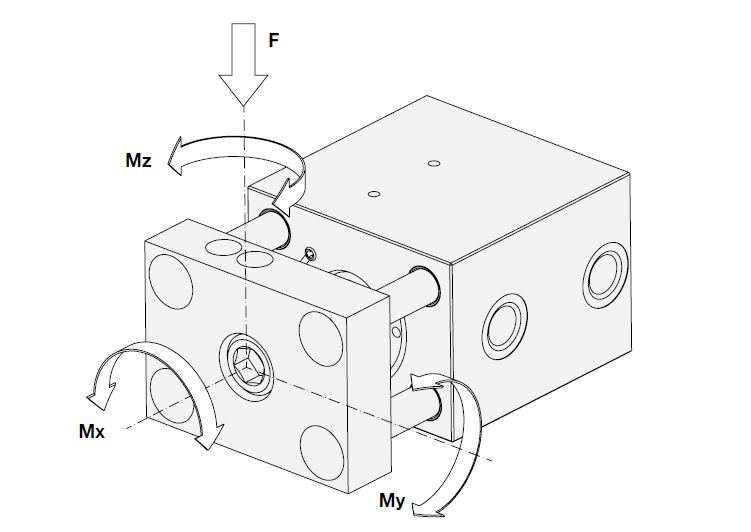

If the front block is loaded with side loads and moments, guide rods will be deformed.

This deformation is as bigger as longer the stroke.

The following assumptions are valid for the maximum moments and side loads recommended in

the diagrams: