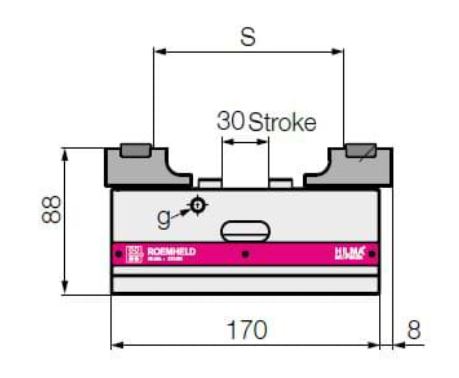

WS5.4503

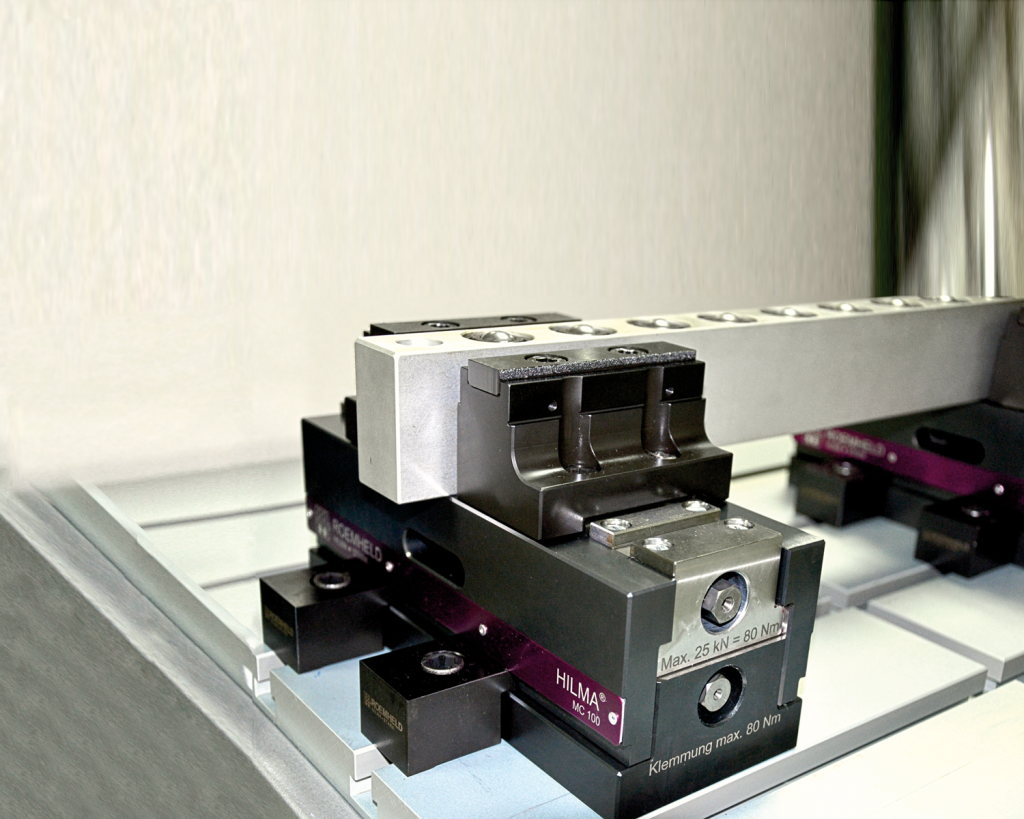

MCP/ZB-Series 5-Axis Position-Flexible

position-flexible clamping, mechanical operation

Features

- patented sliding-jaw segment design

- available in the the two sizes

- jaws provide a floating clamping point that adjusts to the workpiece before locking, to prevent deformation

Check Price & Availability on CarrLane.com

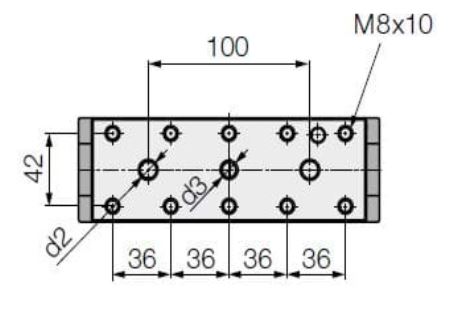

ZB-series MCP vises are concentric position-flexible vises with two moving jaws that provide a floating clamping point that adjusts to the workpiece before locking, to prevent deformation. When turning the clamping spindle, the two clamping slides first concentrically approach the workpiece. After the first clamping jaw reaches the workpiece, only the second clamping jaw moves until both jaws are in contact with the workpiece. Only then is clamping force applied to the workpiece and clamping position fixed. Available in the the two sizes shown below, with the following jaw widths:

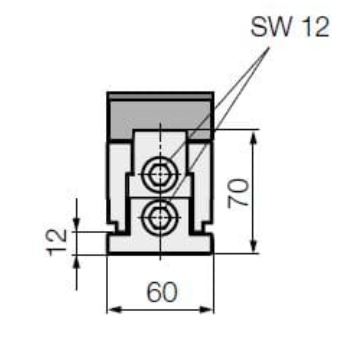

60mm

100mm

The MCP series is a further refinement of our high-precision MC vise series. These new vises combine a very compact, fully enclosed design with a patented sliding-jaw segment design. Thanks to the adjusting spindle arranged in the upper part of the housing, deformation in the base during clamping is reduced to a minimum, providing high rigidity of the entire workholding system. The patented segment design ensures a high degree of precision and stability, reducing guiding clearance to nearly zero.

The position-flexible workholding system MC-P Z Balance has a floating clamping point (with released locking). After operation of the clamping spindle, first the two clamping slides concentrically approach the workpiece. When the first clamping jaw has reached the workpiece, only the second clamping bar will be moved until both clamping jaws are in contact with the workpiece. Only then, the desired clamping force will be introduced into the workpiece using a torque wrench. Subsequently, the clamping position is fixed with the locking spindle. The adaptation of the clamping point to the workpiece position will prevent a deformation of the workpiece.