Low Pressure Swing Clamp

1000 psi max

Features

- double acting only

- top flange

- available in four clamp sizes

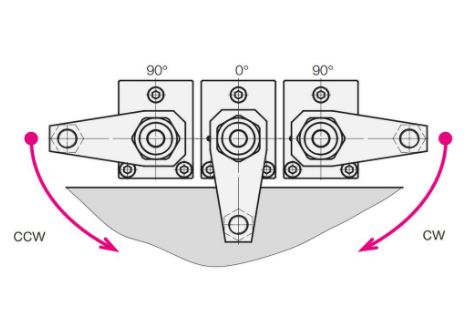

- choice of clockwise, counterclockwise, or zero° swing

- available with 45° and 60° swing angles by special order

- clamping force at 1000 psi with a Standard Clamping Arm

Check Price & Availability on CarrLane.com

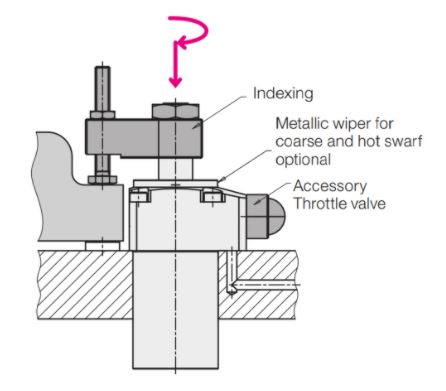

Clamping Action

Swing Clamps are pull-type cylinders where part of the total stroke is used to swing the piston, and the remaining stroke is available as the clamping range. Applying fluid pressure to the A (clamping) port swings arm 90° over workpiece then clamps down. Switching pressure to the B (unclamping) port positively lifts arm then swings it back 90° for loading/unloading.

Reinforced Swing Mechanism

Reinforced swing mechanism ensures positive arm position. The safety-clutch mechanism normally incorporated into our swing clamps is omitted in this design. In case the workpiece hits the clamping arm during loading, the angular position of the swing-clamp arm will be exactly maintained. Using a longer, heavier clamping arm will also not declutch the swing arm and affect arm position.

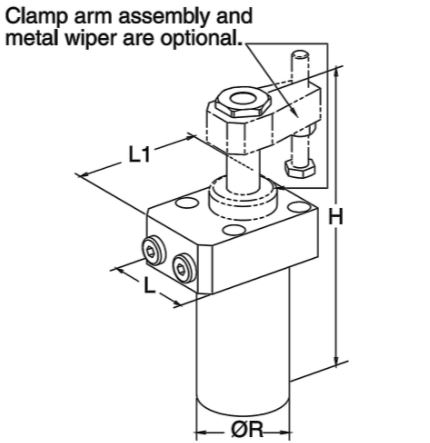

Mounting and Fluid Supply

standard fittings manifold mountings

Dual mounting capability allows any clamp to be mounted using standard fittings or manifold mounting. Two 1/4″ BSPP ports. For optional manifold mounting, use the O-ring ports underneath, instead of the standard ports. Do not use NPT fittings. For manifold mounting, the mounting surface must be ground flat to ensure proper O-ring sealing. Fasten clamp with four socket-head cap screws.

Clamping Arms

Order clamping arm separately – see clamping accessories. The maximum allowable operating pressure is 5000 psi. Longer, custom clamping arms will reduce allowable operating pressure, inversely proportional to arm length. Optionally, the clamping arm can be positively keyed to the piston rod in a fixed 90° position by inserting an indexing pin (order separately).