B1.849 (1 Series)

Compact Swing Clamp – Threaded Cartridge

Single or double acting

Features

- available in one clamp size,

- single-acting or double-acting

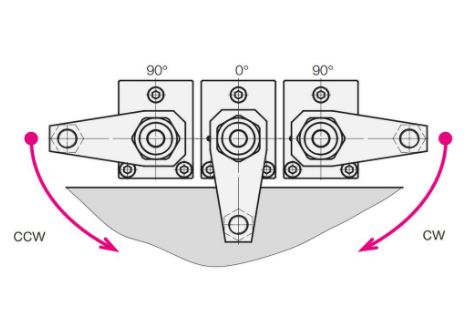

- with a choice of clockwise, counterclockwise, or zero° swing

- available with 45° and 60° swing angles by special order

- clamping force at 5000 psi for single-acting clamps with a standard arm:

- 5000 psi max

Check Price & Availability on CarrLane.com

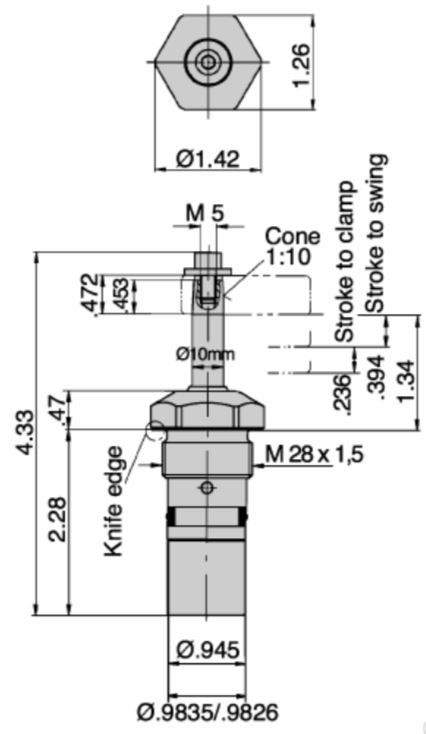

Swing Clamps utilize a sturdy helical-cam mechanism to swing the clamping arm clear for unrestricted loading. The Compact Swing Clamps shown here are extremely small, economical clamps suitable for many applications. The clamping arm can be mounted to start its 90° swing from any position within 360°. The threaded-cartridge version is designed specifically for space-saving manifold mounting.

Available in one clamp size, single acting (shown here) or double-acting (see Related Products below), with a choice of clockwise, counterclockwise, or zero° swing. Available with 45° and 60° swing angles by special order. Clamping force at 5000 psi for single-acting clamps with a standard arm: 450 lbs (1 series)

Design Consideration

Due to their small size, these Swing Clamps do not have overload protection; therefore the swing motion must not be restricted in any way. Be sure to adjust the contact bolt so that the clamp completes its full swing stroke and starts its clamping stroke before contacting the workpiece. To be safe, use low operating pressure during initial setup.

Do not exceed maximum fluid flow rate in table. For extended clamp life a simple flow-control valve may be required if the fixture is powered by a high-flow-rate power source and only contains a few clamps. Clamping time should be at least one second.

Clamping Action

Swing Clamps are pull-type cylinders where part of the total stroke is used to swing the piston, and the remaining stroke is available as the clamping range. Applying fluid pressure swings arm 90° over workpiece then clamps down. The single-acting version shown here has a fast, totally dependable spring return that lifts the arm, then swings it back 90° for loading/unloading.]

Clamping Arm

Order clamping arm, screw, and washer separately – see clamping accessories. Clamping arm includes a contact bolt. Standard clamping arm (5000 psi max).

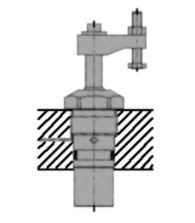

Mounting & Fluid Supply

|

Screw clamp into fixture up to the body hex. Threaded-cartridge clamps have O-ring seals on their outside diameter, so they require a precision mounting hole. Carefully follow hole-preparation instructions in the drawings. Fluid passages must be drilled exactly as shown in the drawings. Do not use NPT fittings. |