ROEMHELD’s assembly and handling solutions bring increased operator safety and ergonomics to a wide range of industries including automotive, aerospace, medical, plastics and rubber, food and packaging. Our assembly systems can be combined in numerous ways for safe and efficient handling of light to heavy loads in assembly operations. Various modules provide horizontal and vertical rotating, tilting, and lifting of workpieces with mechanical, hydromechanical, or electric operation. Each module can be used individually since they are independent functional units, or several can be combined together to create a multi-functional unit.

Product Categories

Click Below!

|

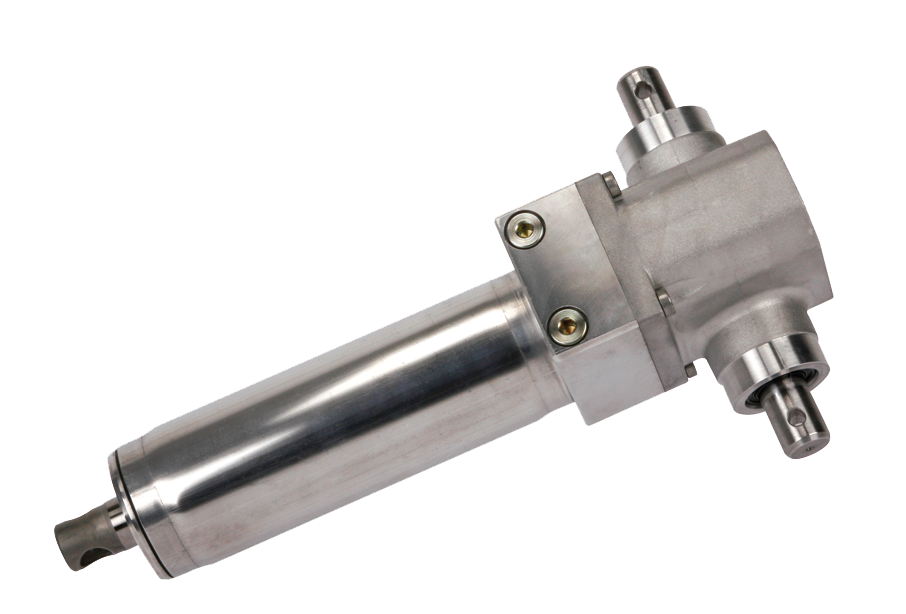

Linear Actuators

|

Foot-operated Hydraulic Linear Actuator Pump used as a base in a hospital bed for height adjustment applications. |

ROEMHELD’s RH 1250 model, pictured here, is ideal for medical applications like the Rifton activity chair as well as other lifting applications. They have a max lifting force of 4.5 to 12.5 N, and can include a foot pedal or hand lever operation. Available in electric or hydraulic. Principal use

|

|

|

|

|

|

Modular Units/Lifting Column (see below)

|

|

Combine modular units for safe, efficient handling. Achieve rotating, tilting, and lifting of workpieces, and use with carts, floor modules, plates, clamps, or adjustable tables. Learn more below on the specific module pieces. Principal use

|

See the Chart Below for Information on specific modules for your application

| IMAGE | MODULAR UNIT | DESCRIPTION |

|

Rotating Module Horizontal Axis | Rotate your workpiece about the horizontal axis via manual, hand lever, or hydromechanical operation. A 4 x 90˚ indexable version is available. Maximum weight is 200 kg (450 lbs). Data sheet: M1.101. |

|

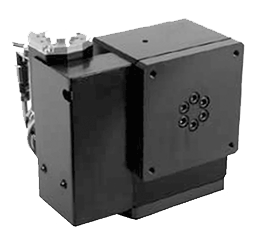

Rotating Module, Electric, Horizontal or Vertical Axis | Rotate your workpiece from 0˚ to 90˚ via electric operation. Versions for horizontal or vertical rotation. Maximum weight is 600 kg (1,350 lbs). Data sheet: M1.201. |

|

Rotating Module Vertical Axis | Rotate your workpiece about the vertical axis via manual or hydromechanical operation. Standard version is indexable 4 x 90˚. Special index angles available upon request. Maximum weight is 600 kg (1,350 lbs). Data sheet: M1.301. |

|

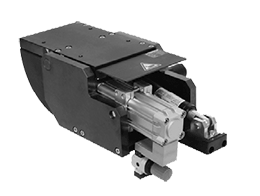

Tilting Module | Tilt or swivel your workpiece from 0˚ to 90˚ via manual or electric operation. Maximum weight is 100 kg (225 lbs). Data sheets: M2.101, M2.201. |

|

Lifting Columns | Precision lifting and lowering of your workpiece. Electric and self-contained hydraulic versions. Electric versions can be synchronized. Telescoping versions available too. Maximum weight is 100 – 600 kg (225 – 1,350 lbs). Maximum stroke is 200 – 1000 mm (7.87″ – 39.4″). Data sheets: M4.005, M4.101, M4.202, M4.203, M4.301, M4.401, M4.402, M4.501. |

|

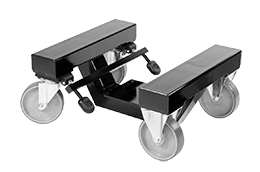

Cart Modules | Heavy duty carts are designed to interface and move individual modules or modular combinations, with or without their workpiece. All carts are equipped with a parking brake. Data sheet: M5.101. |

|

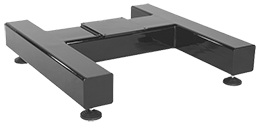

Floor Modules | Heavy duty floor modules come equipped with leveling feet and you can mount one or more individual modules on the same base. Data sheet: M6.101. |

|

Accessories | Base Plates, Flange Plates, Table Plates, Adaptor Plates, Clamping Modules, Power Supply Units, Hand Panels & Foot Switches. Data sheets: M8.100, M8.110, M8.120, M8.130, M8.131, M8.200, M8.201, M8.203, M8.300, M8.301, M8.302.

|

Why use ROEMHELD Assembly and Handling Solutions?

ROEMHELD delivers modular systems. This gives high flexibility to the customer to integrate their own constructions and vises into the system. In addition, you always have a choice between manual and powered designs. You can start with easy assistance and develop up to semi-automatic systems. We target manual assembly of any goods, with weights from 20 to 300 lb (10 to 150 kg), even up to 1,300 lb (600 kg) for some applications. The biggest benefits come from the flexibility to combine the various systems in ways that meet the user’s varying needs.

Why is ergonomics important in an assembly line?

Ergonomics in an assembly line is important to reduce injury, create higher productivity, and boost morale in the workplace. Not all injuries are instant, some happen over time the resulting in repetitive motion disorder. To reduce the risk of this disorder you can implement ROEMHELD’s assembly systems and make your assembly line ergonomic. With our systems you can expect:

- Height-adjustable working tables

- Modules for rotating, tilting, and swiveling workpieces for adjusting the optimal workpiece position

- Clamping modules and fixture mounting devices for quick and safe fixturing of a workpiece

- Cart Modules for when your modular units need to be mobile.

Videos l Assembly & Handling Catalog I Request Literature