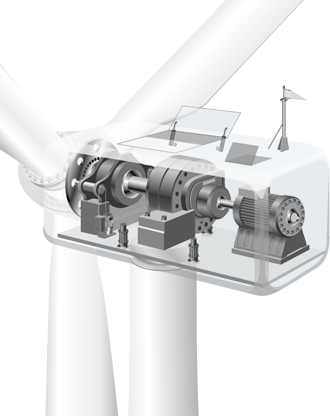

Rotor Locks for Wind Power Plants

ROEMHELD has introduced a new rotor lock designed to deliver increased availability and simplified maintenance to wind power plants. A new, special coating on these products prevents the locking bolt from rusting when not in use for a long period and non-contact position monitoring avoids mechanical wear and extends the life of the component.

A permanently corrosion-free coating of the bushings prevents rusting between surface intervals and the need for regular greasing. As a result, the rotor lock is permanently ready for use which also reduces the need for plant maintenance. The surface protection of all rotor lock components corresponds to DIN ISO 12944, C4, so that they can also be used in offshore operations.

How ROEMHELD Rotor Locks Work

ROEMHELD rotor lock works with hydraulic or electromechanical locking mechanism and withstands side loads up to 5,500 kN. The double-acting hydraulic cylinder generates the retracting and extending motion of the bolt and reliably locks the rotor blade of wind power plants up to 6.5 megawatts of power within a temperature range from – 30°C to + 70 °C. A mechanical or inductive position monitoring of the bolt transmits the final positions “Rotor blade secured” and “Rotor free” to the system control and ensures additional safety. The locking module, with its compact design, is adapted to the limited space in the nacelle. The use of standardized tooling components makes it possible to produce complex special designs quickly and cost-effectively.

Non-contact position monitoring has also been introduced by ROEMHELD to offer longer life and high availability. A non-contact switch checks if the bolt is in stand-by position or if the rotor is locked. As there are no mechanical contacts to wear out, replacement is not necessary.

Product Highlights

Click Below!

|

|

Hydraulic and Electromechanical Rotor LockThese modular rotor locks are designed for onshore and offshore wind turbines and are distinguished by their compact, low-maintenance design.

|

|

|

Electrical flap operationThe ROEMHELD linear actuator RA 600 actuates flaps and hatches automatically at the push of a button. Available in your choice of hydraulic or electric, these products:

4Learn more about this product

|

Videos l Assembly & Handling Catalog I Request Literature