By Kate Bachman, Editor

Article from May 2014 issue of Stamping Journal.

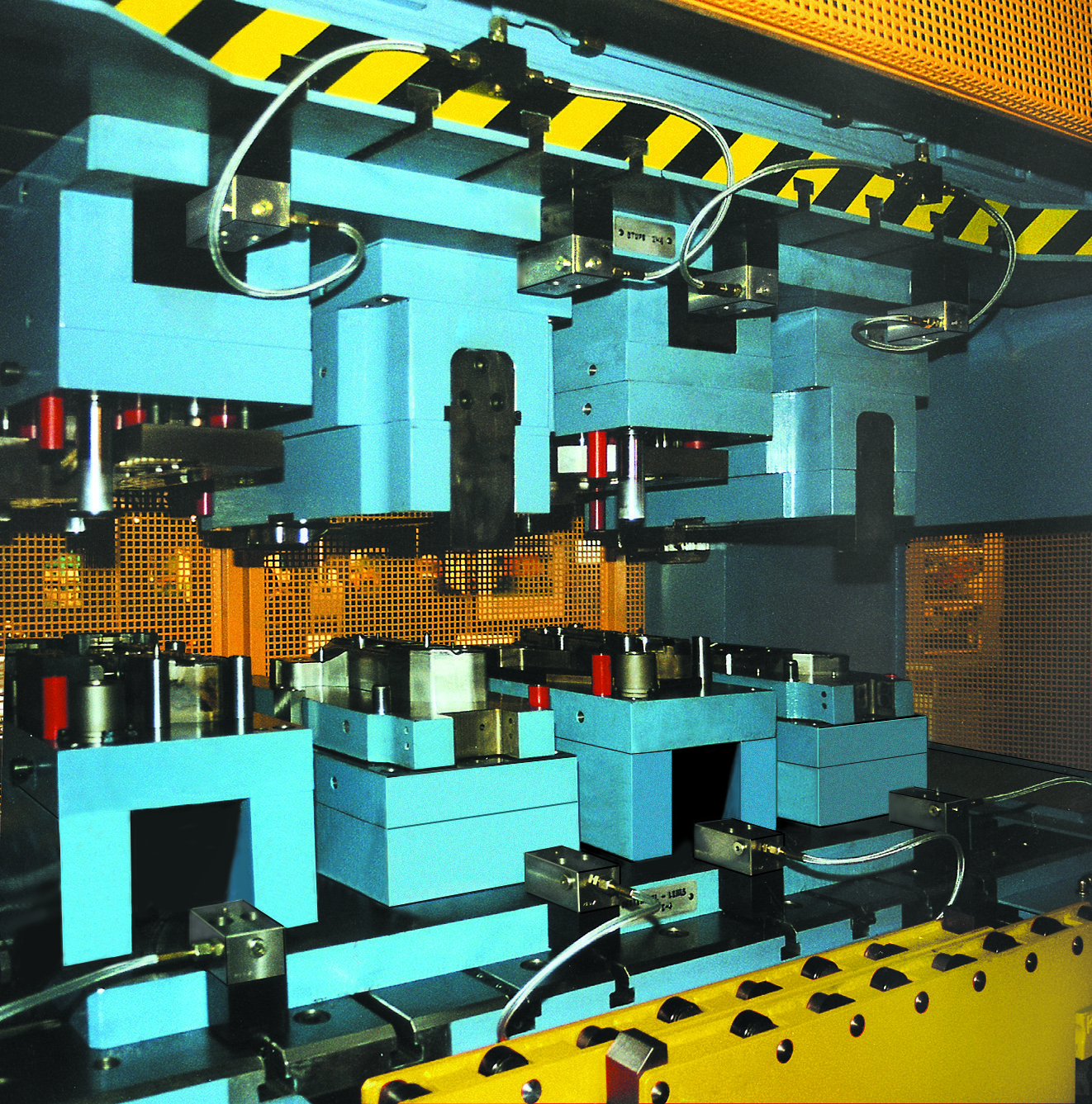

(Partial article. Use this link to read it in full):Quick die change, introduced decades ago, has become a staple of lean manufacturing in most stamping shops. QDC equipment itself is being upgraded and their lines expanded to meet evolving requirements for speed and safety, including force evaluation systems on magnetic die clamping, auto-positioning, auto-clamping, thinner magnetic clamping plates, trackless carts, and automated storage and retrieval systems.

David L. Fischer, Hilma engineering manager, Carr Lane Roemheld Mfg. Co., pointed to production volume variation as a push for even faster die changeovers and economical die clamp and handling systems. “Shorter runs and more frequent die changes mean more press downtime. So die changes must be quicker.” He added this caveat: “But safety cannot be sacrificed for speed; they need safe clamping systems and ergonomic die exchanges.”

“We have a variety of products that can provide custom clamping and handling for most applications, with a mix of standard products,” Fischer said. “Newer components include smaller and more economical electrical and pneumatic power units, suitable for small and midsize QDC systems and presses.

“Additional die handling products include hydraulic or spring-actuated ball and roller lifters. The positions and spacing of balls and rollers in the lifter bars can be adjusted to fit the application. This can greatly reduce costs when moving lighter dies. Ergonomic hydromechanical manual clamps, with clamp force indicator pins, can provide high clamp forces and very little tightening torque.”

“We work directly with the user to customize a system for their needs,” Fischer said. “This includes types and quantities of clamps, die rollers, die supports, pumps, and valves.”

Read the full article on

Fabricator/Stamping Journal’s web site