Products for the Machining Industry

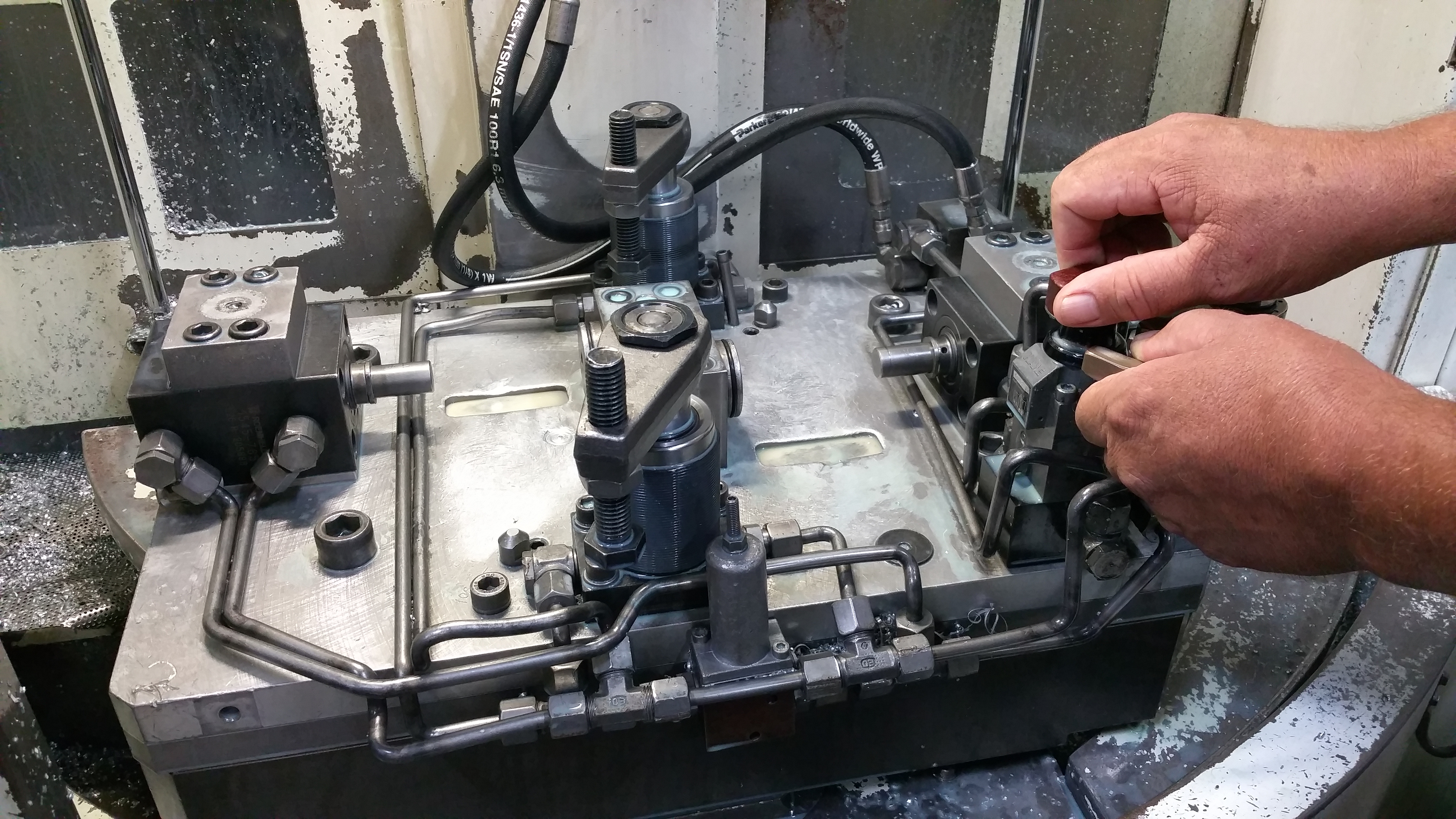

ROEMHELD provides a full selection of state-of-the-art, air and hydraulically powered components and accessories for the machining industry. More than 80 different types of power workholding devices are available, allowing you to speed up and streamline many manual workholding operations. Compact, yet able to operate comfortably at 7,500 psi, power workholding products include flexible clamping systems, swing clamps, push clamps and cylinders, work supports, coupling systems, collet vises, and many other workholding items.

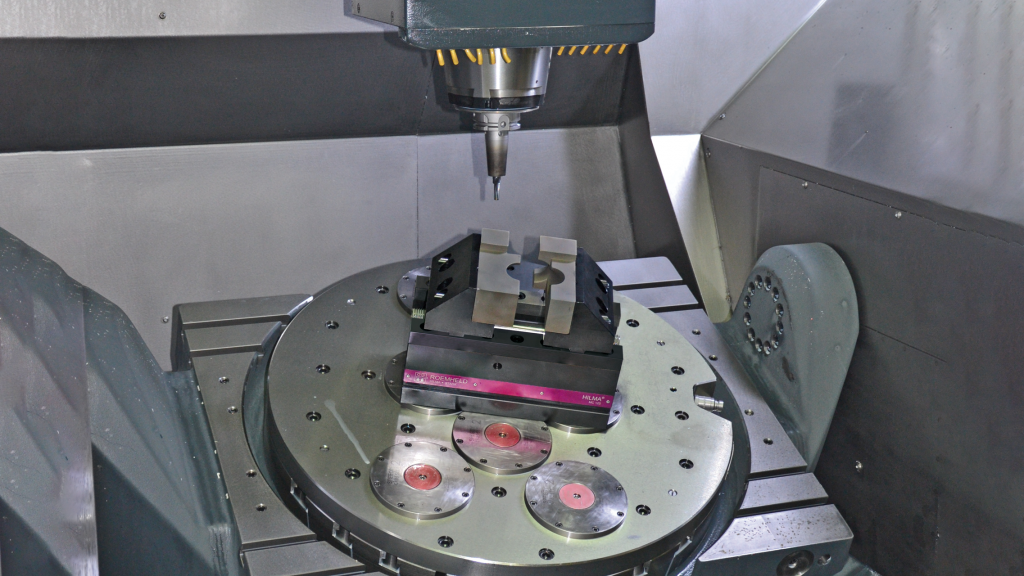

– CNC Precision Machine Vises Solutions –

ROEMHELD offers a wide assortment of precision machine vises for CNC machines and milling operations with horizontal and vertical mounting options. Manufactured in Germany, vises from Roemheld are made to last. They are made of the finest-quality construction, with a special cast steel base for excellent rigidity, dimensional stability, and durability. Fully hydraulic and hydro-mechanical versions of these machine vises provide the consistent clamping force required for high-speed machining, significantly reducing operator fatigue. Precision vises are designed to hold many different workpieces, and come in three versions: 5-axis vises, machine vises, and self-centering vises delivering clamping forces up to 22,500 lbs.

|

Product Spotlight NEW PC-80 Vise

|

PC80 Clamping system features a simple, compact all-steel design, and includes clamping jaws with a dovetail shaped serrated gripping feature. The all-steel design provides the highest force, most rigid, design in 5-Axis vises. The Jaw assembly is simple to remove ensuring quick and easy cleaning and maintenance. The PC80 features several mounting options including the use of competitor Zero-Point 52mm pins or the use of a Quintus Pull-Down Bolt. The sides of the base include grooves for permanent installation with clamping claws. Watch a Video!

|

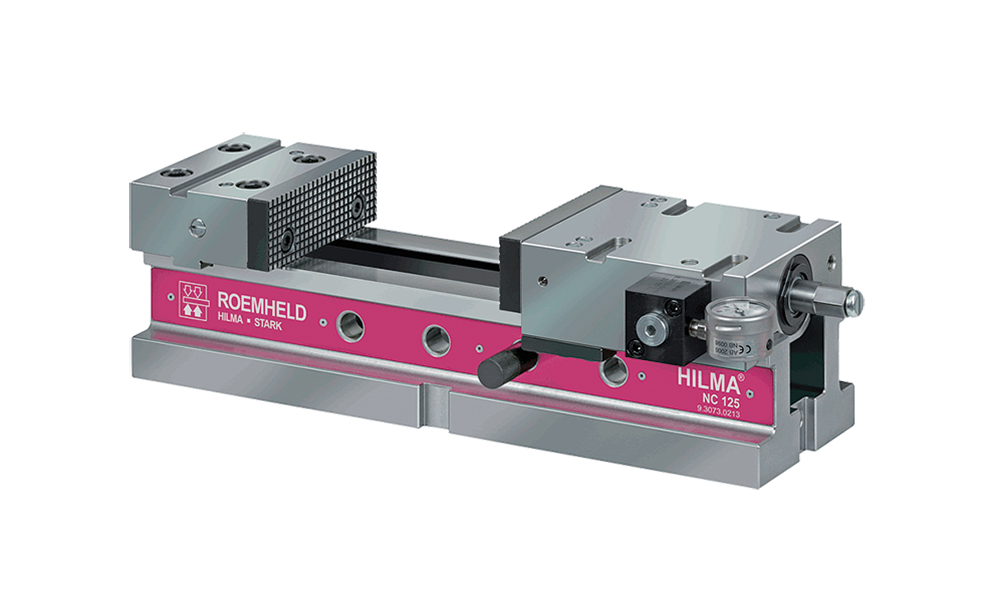

NC Series

|

NC vises are available in hydromechanical or fully hydraulic versions, in three jaw widths, with an optional clamp force indicator. The vises deliver a high 0.0004″ repeatability, and clamping forces from 5600 lb to 14,000 lb. The optional clamping force display allows a continuous and precise clamping force application. The high-precision reproducibility of the clamping forces guarantees a maximum possible repetitive accuracy of the clamping processes.

|

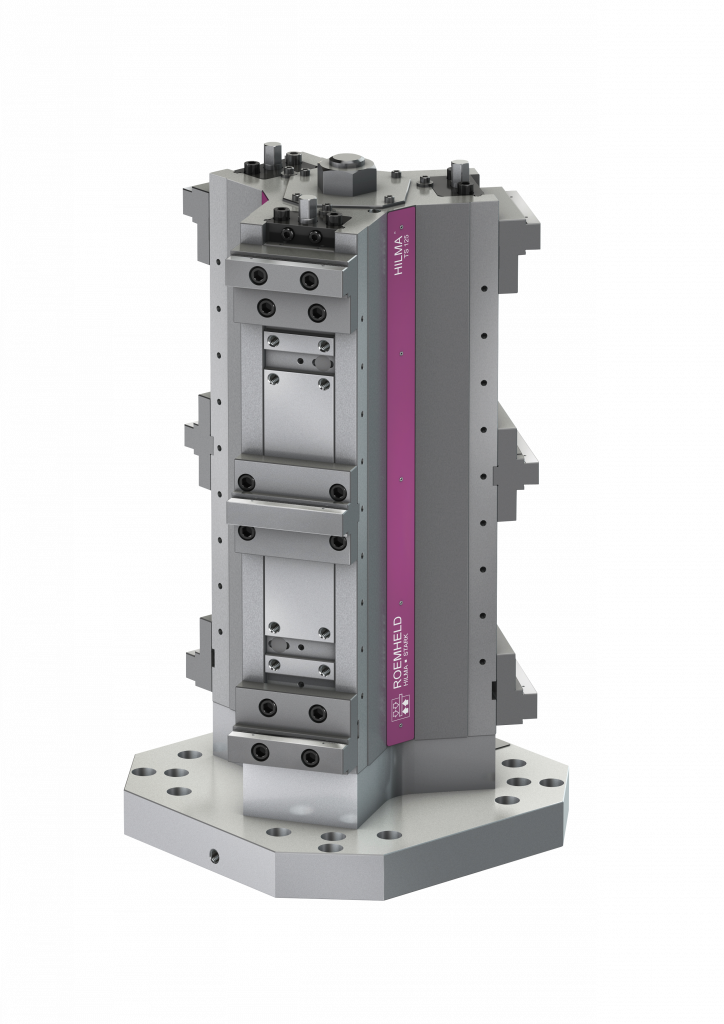

TS Tri-Star Vise

|

TS TriStar Machine Vise tower workholding systems used on horizontal machining centers, in vertical machining in connection with 4th axis, but also on 5-axis machining centers.

|

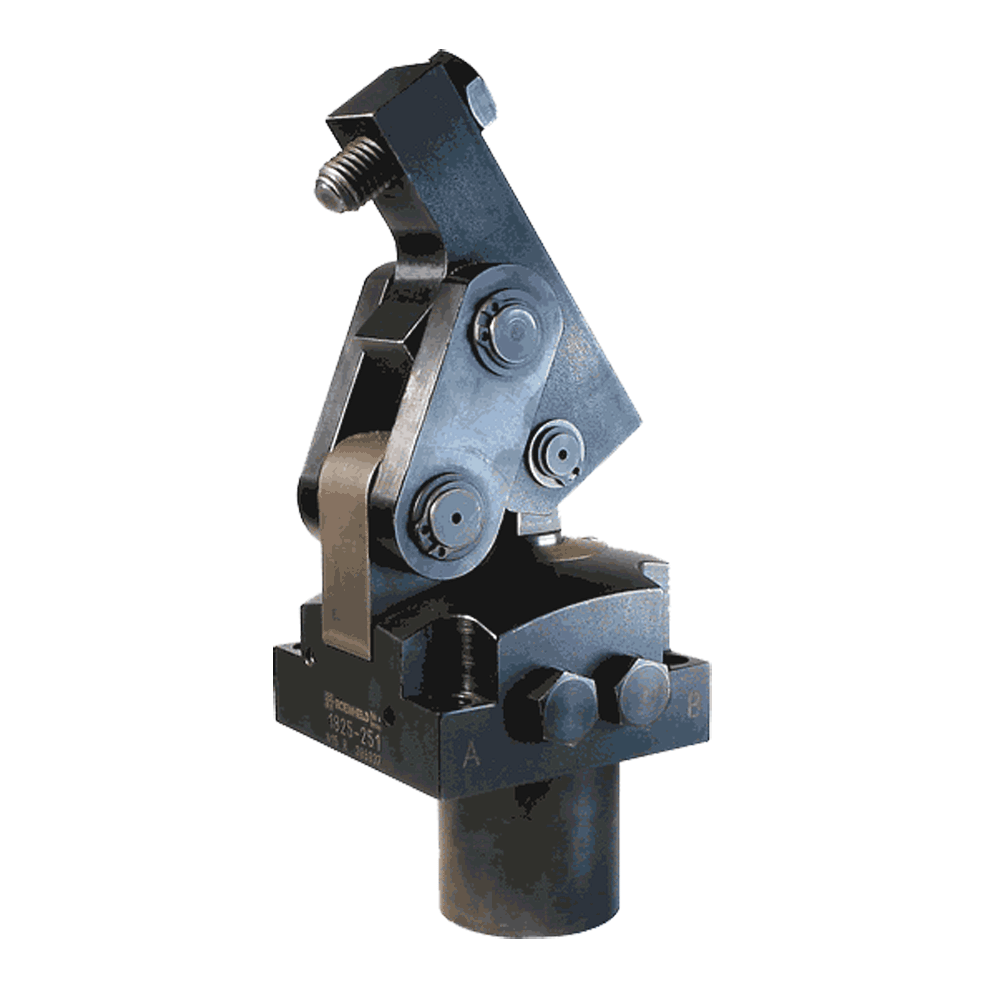

- – Swing Clamp Solutions –

Swing clamps are devices, which use a swinging clamp arm to speed up clamping and unclamping. They utilize a sturdy helical-cam mechanism to swing the clamping arm clear for unrestricted loading. They are are popular in repetitive operations. ROEMHELD’s swing clamps come in 5 varieties including mini, compact, standard, robust, and air powered. We also offer a variety of swing clamp accessories. Each swing clamp-type has a variety of different clamps to meet your machining needs. Browse our large variety of swing clamps here.

|

Low Pressure Swing Clamps

|

This unique series of Swing Clamps provides considerable clamping force at lower hydraulic pressures, allowing direct connection to the low-pressure hydraulic system of a machine tool. These are extremely compact, heavy-duty clamps with a reinforced swing mechanism and a heavier clamping arm to exert high clamping force in relation to clamp size. Swing Clamps utilize a sturdy helical-cam mechanism to swing the clamping arm clear for unrestricted loading. Arm can be mounted to start its 90° swing from any position within 360°

|

Air Powered Swing Clamp – All Threaded

|

Air-operated version of our popular Hydraulic Swing Clamps, for applications requiring light clamping force. Arm swings clear for easy loading, with a sturdy helical-cam mechanism. Arm can be mounted to start its 90° swing from any position within 360°. A standard magnetic piston allows monitoring of clamping and unclamping position. The all-threaded version shown here is ideal for mounting through a fixture plate, to keep air lines out of the working area. An optional flange base is available for additional mounting possibilities.

|

Automation Swing Clamp – Top Flange |

Special series of double-acting Swing Clamps designed for automated high production. Top-flange version allows low mounting, using either standard fittings or manifold mounting. Reinforced swing mechanism ensures positive arm position. Extended helix rod for built-in pneumatic or electrical position-monitoring capability.

|

- – Threaded Body Cylinder Solutions –

ROEMHELD has a large selection of threaded body work support cylinders. All threaded cylinders come in a wide range of sizes with mounting and fluid supply options. Threaded-body clamps provide considerable force in small size and may be threaded directly into tapped holes of the fixture. They can be used to great advantage in fixtures where space is at a premium. Hydraulic fluid is supplied through passages drilled into the fixture body, eliminating hydraulic hoses and threaded fittings. The built-in spring returns the piston when hydraulic pressure is released.

Each threaded insert is manufactured with steel and has a black oxide finish. Browse our large selection of threaded cylinders below.

|

Mini Threaded-Body Work Supports

|

The support plunger is hydraulically extended and retracted by means of a small single or double-acting cylinder. Contact to the workpiece is made by spring force. The pressure spring can be easily exchanged. The support plunger is additionally guided in the area of the shaft diameter and can therefore absorb side loads up to 300 N.

|

| Threaded-Body Work Supports 70 bar

|

Versatile push clamps that provide considerable force in a small size. These small clamps can be placed very close together, especially when manifold mounted. Clamps can be screwed all the way down to their hex flats, or installed at partial depth. Long plunger guide ensures excellent reliability and durability. Available in five body diameters, with inch or metric threads, with a choice of tapped plunger (shown here), radius plunger, or swivel plunger.

|

- – Extending Clamp Solutions –

ROEMHELD hydraulic extending clamps have a sturdy lever mechanism that extends into clamping position, and retracts for loading. Our extending clamps are available in a variety of clamps including compact clamps, hinge clamps, slide pivot clamps, flat clamps, block extending clamps, and low-block edge clamps.

|

Hinge Clamp w/ Flat Clamping Lever

|

Hinge Clamps have a sturdy linkage configuration that moves the clamping arm forward as it pivots into clamping position. This specially designed linkage allows the clamp to exert nearly perfectly vertical clamping force. The clamping arm retracts fully for clear loading from above. Ideal for clamping in narrow recesses. Durable, economical clamp with an easy-to-clean mechanism and standard metallic wiper.

|

|

Mini Compact Clamps

|

Mini compact clamps are designed for application in hydraulic clamping fixtures where oil supply is effected through drilled channels in the fixture body. Clamping force of 20-290 lbf.

|

| Hinge Clamps with Throttle Valve 70 bar

|

Hydraulic Hinge Clamps are designed for the direct connection to the low pressure hydraulics of machine tools. Special kinematics allow clamping without side loads of workpieces which are very sensitive against deformation. Clamping force of 515-3865 lbs.

|

- – Work Support Solutions –

ROEMHELD hydraulic extending clamps have a sturdy lever mechanism that extends into clamping position, and retracts for loading. Our extending clamps are available in a variety of clamps including compact clamps, hinge clamps, slide pivot clamps, flat clamps, block extending clamps, and low-block edge clamps. Hydraulic Work Supports automatically adjust to the proper height for supporting a workpiece, then lock securely to become fixed rests. The support plunger on these pneumatic work supports is held by a precision sliding-fit pressure sleeve that provides incredible accuracy and repeatability. The hydraulic work support types shown below are available in spring-extended, fluid-advanced, and air-advanced versions

Threaded-Body Work Supports – spring extended/fluid/air advanced

|

Fluid-advanced Work Supports provide extra loading clearance and are ideal for workpieces that are too light to depress a spring-loaded plunger. Air-advanced Work Supports allow fine-tuning contact force using a Fine Air Pressure Regulator, and provide separate control of plunger advance. The mini threaded-body version shown here is amazingly compact. Manifold mounting capability allows space-saving low-height installation. Hardened contact bolt furnished.

|

Flange-Base Work Supports – Spring Extended

|

Work Supports automatically adjust to the proper height for supporting a workpiece, then lock securely to become fixed rests. The flange-base version shown here has a long stroke with high load capacity and provides many mounting options. Available in two sizes, with inch or metric plunger threads. Choice of two versions: Type 1 with side BSPP port, or Type 2 with bottom BSPP port. Load capacity at 7250 psi:

|

View All Products

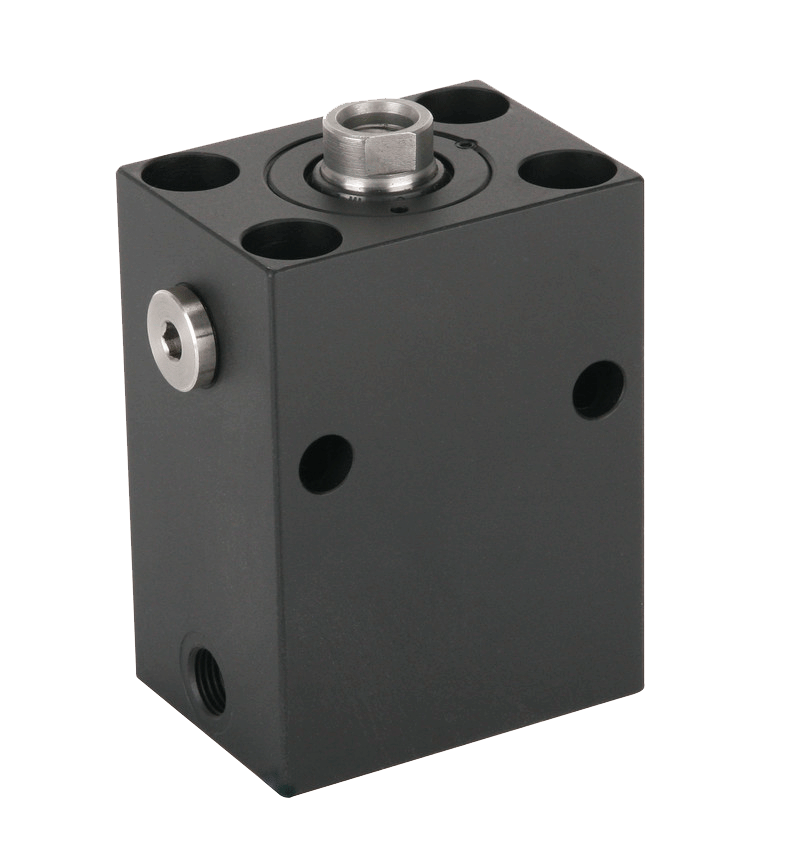

– Block Cylinder Solutions –

Hydraulic Block Cylinders made by ROEMHELD provide a compact design that is easy to mount on flat surfaces, horizontally or vertically. These hydraulic block cylinders are excellent for punching, pressing, and assembly operations, with very high forces available. Hydraulic Block Cylinders are available in a wide range of sizes with many mounting and fluid-supply options. They are single or double acting, and are made of high alloy steel, bronze alloy and special aluminium alloys. ROEMHELD block cylinders do not leak oil when static. Stroke leakage is at a minimum due to the double piston sealing.

|

Block Cylinder – SIngle Acting

|

Compact design with many applications. Easy to mount on flat surfaces, horizontally or vertically. Excellent for punching, pressing, and assembly operations, with very high forces available.

|

ROEMHELD Block Cylinders with Position Monitoring – Double Acting

|

These double-acting Block Cylinders have an aluminum body and a magnetic piston, to allow using Magnetic Sensors for position monitoring (order Magnetic Sensors and Connecting Cables separately). Compact design with many applications. Easy to mount on flat surfaces, horizontally or vertically. Excellent for pressing and assembly operations, with high forces available. Can also be used for pulling, by reversing the A and B ports.

|

View All Products

What is Power Workholding?

Hydraulic and pneumatic clamping has long been a part of manufacturing. Only with the recent introduction of hydraulic systems specifically designed for workholding applications has power clamping emerged as an everyday workholding alternative. This is due, in large part, to the increased demand for faster production and more automation on newer machine tools. But faster production is only one reason for the appeal of power workholding. Today’s power-workholding systems offer a wide range of options and capabilities. To make full use of the systems, one must first understand the basic principles of power workholding as well as the range of available components.

Why use Power Workholding?

AUTOMATION

Power-operated elements provide more control and a wide range of operations within a workholding system. Once adjusted, each product consistently clamps or holds. Powered work supports automatically adjust to minor workpiece irregularities. In addition, power workholding systems can operate multiple clamps and other devices in sequence to accomplish a multistep fixturing task.

SPEED AND SAFETY

Power Workholding Components greatly reduce loading times and are particularly effective for high-volume runs. Although initial costs are higher than with mechanical workholding, self-contained hydraulic workholding products are more efficient because fewer clamps (and accompanying personnel to operate them) are required. By replacing repetitive manual clamping, power workholders reduce operator fatigue. They allow remote control of inaccessible fixturing. Most systems also feature back-up controls for added safety in case of power failure.

UNIFORM CLAMPING FORCE

Since power workholders are controlled by a power source, the strength and fatigue of the operator have no effect on clamping force. Once set, force remains constant. And when more or less force is required for the next setup, the same clamps or positioners can beadjusted for those specific conditions.

SIMPLIFIED OPERATION

When operators have less physical labor in clamping and unclamping, they can run more machines and produce more. More workpieces can be loaded on fixtures for a given production cycle, which lengthens individual steps and requires less attention from the operator. Many types of power workholding can be performed by less-skilled workers.

N/C COMPATIBILITY

Versatile power workholding does not require design specialists. The same tool designer who designs the workholder can also design the clamping system. With their small size, Roemheld components are easy to locate. Standard fittings connect easily and ensure positive sealing.

COMPACTNESS

Roemheld power components are designed to fit easily on fixtures. Since they function well at fluid pressures up to 7500 psi, their smaller design can still provide high clamping forces. Small power clamps often allow loading more workpieces on a fixture because the clamps can be positioned closer together. A result is increased productivity through more parts per cycle.

To learn more about how Power Workholding will help you create a more efficient and competitive production environment, call our Engineering Department from the United States and Canada at 636-386-8022.