Die Clamping Technology

ROEMHELD Hilma is a worldwide market leader in quick die change systems and products. We offer the most complete range of die clamping and handling systems in the industry for applications with mechanical presses, hydraulic presses, forging presses, injection molding machines, and die-cast machines. To survive in today’s competitive worldwide market, manufacturers are reducing inventory costs by running smaller batch sizes and making shorter production runs. One way to maximize press uptime in an environment like this is to implement faster more effective die changes.

The Quick Die Change System helps manufacturers accomplish these goals, shortening die change time and making facilities more productive and profitable. Learn more about the full line of quick die change products and how they help drastically reduce downtime, increase production runs, and more.

Magnetic Clamping Technology

ROEMHELD’s magnetic clamping systems by RIVI Magnetics are designed for metal stamping presses, plastic injection molding machines, and rubber molding machines. The systems include square or long pole technology providing M-TECS power concentration and are resistant to high temperatures up to 464°F

See Products.

Hydraulic Clamping Elements (Integrated)

ROEMHELD hydraulic clamping elements, are integrated into the press/machine. The design of these clamping systems ensures the optimum use of the bed or slide without any colliding edges during die positioning.

See Products.

Hydraulic Clamping Elements (Stationary)

ROEMHELD stationary hydraulic clamping elements are installed in a fixed position, e.g. on press beds of machines. These products are compact and well-proved clamping elements with maximum clamping forces. Included in this section are wedge clamps, clamping bars, double-T bars, spring clamping cylinders, extending clamps, wedge swing clamps, pivot and pull clamps. View Catalog –…

See Products.

Hydraulic Clamping Elements (Adjustable)

ROEMHELD adjustable hydraulic clamping elements, are positioned by moving them in T-slots provided on the press/machine and are ideal for retrofitting without the need to standardize die widths. Included in this section are hollow piston cylinders and sliding clamps, plus automatic systems with push-pull chains or pneumatic cylinders to move the clamp during the die…

See Products.

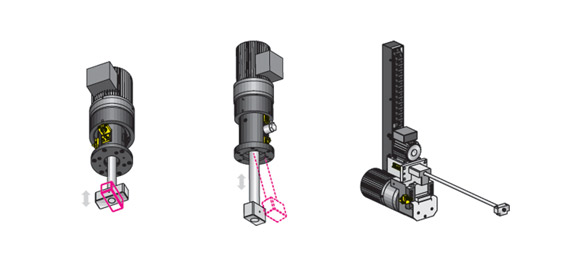

Electromechanical Clamping Elements

ROEMHELD electro-mechanical clamping elements provide maximum operational reliability as a result of mechanical self-locking designs. These clamping systems are recommended for applications where a hydraulic system cannot be used.

See Products.

Mechanical Clamping Elements

Mechanical clamping elements feature a compact design with high power density. High clamping forces and convenient use are of prime importance for customers who choose these clamping elements. ROEMHELD offers sliding clamps, high-pressure spindles & clamping nuts.

See Products.

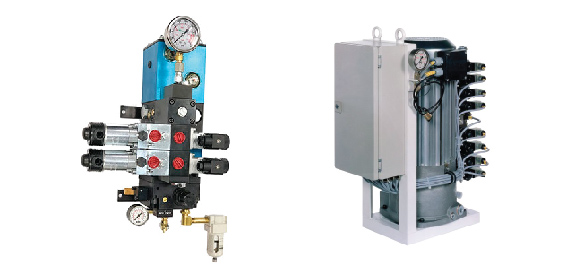

Power Units

ROEMHELD hydraulic or pneumatic-hydraulic power units feature a compact design ready for connection. Hydraulic or pneumatic power units are configured to control all the clamps and lifters in the die change system. Individual solutions are possible by using this unique modular system.

See Products.

Accessories

Browse ROEMHELD accessories for installation of hydraulic clamping elements, e.g. hoses, tubes, couplings, quick disconnects, pressure switches, valves and control elements. A custom installation kit can also be developed for your application.

See Products.

Die Handling

Die handling, e.g. roller bars, ball bars, ball inserts, carrying consoles and die carts. ROEMHELD offers everything for a convenient and safe die change.

See Products.