Grip Rail Coupling

Rapid Action Clamping System for Transfer Presses

Features

- safe coupling and uncoupling in a matter of a few seconds

- positions are reproducible in a very short time

- high positioning accuracy of ± 0.02 mm

- easy retrofit

- no moving parts in the passive part of the coupling, thus making the coupling maintenance-free and affordable

- self-locking

- high dynamic strength

- flexible design of the couplings for electrical power, compressed air and hydraulic fluid as per customer’s specification

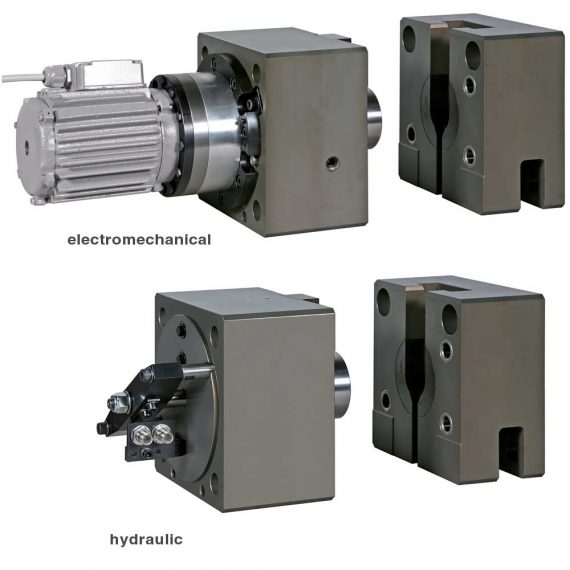

In contrast to conventional systems, the new coupling is designed in such a way that all components for positioning, centering, clamping force build-up and position monitoring are integrated into the active part of the coupling which is firmly connected to the press. The passive part does not have any moving parts.

In order to keep the weight of the coupling low, the housings of both active and the passive parts are made from hard-coated, high-strength aluminium.

When moving the two halves of the coupling into position (insertion of grip rail), these are pre-centered using guide elements. Positioning pins on the active part locate into drilled holes in the passive part, thereby centering the coupling and ensuring a high degree of reproducibility. The clamping force is built up using a tie rod and maintained in a self-locking manner.

A compact position monitoring system installed in the element is easily adaptable to a bus system and this ensures exact positioning and clamping.

As an option, rapid action couplings for electrical power, compressed air and hydraulic fluid can be permitted for the customer’s specification.

The swing clamps are fastened in the press ram. The ram is in the upper position and the swing clamps are extended (die change position).